This is a very basic subject that I would like to talk about, but it is fundamental to understand well that there is a world between this two words. I can always remember that when I had my first Computer Assisted Design (CAD) course in my engineering college in France (the Ecole Centrale of Lille), I was told that CAD was a necessary tool for the engineer, but I never really understood why at that moment.

It is true that sometimes engineers become designers, but, in my mind, the real craving of an engineer is to understand how things work and how to make them better. This is why the best tool for engineer is rather Computer Aided Engineering (CAE).

Why people who don’t know about the topic easily mix between CAD and CAE? Because in the two, you are working on 3D models?

Well, it may be true, but there is a huge difference: the Purpose.

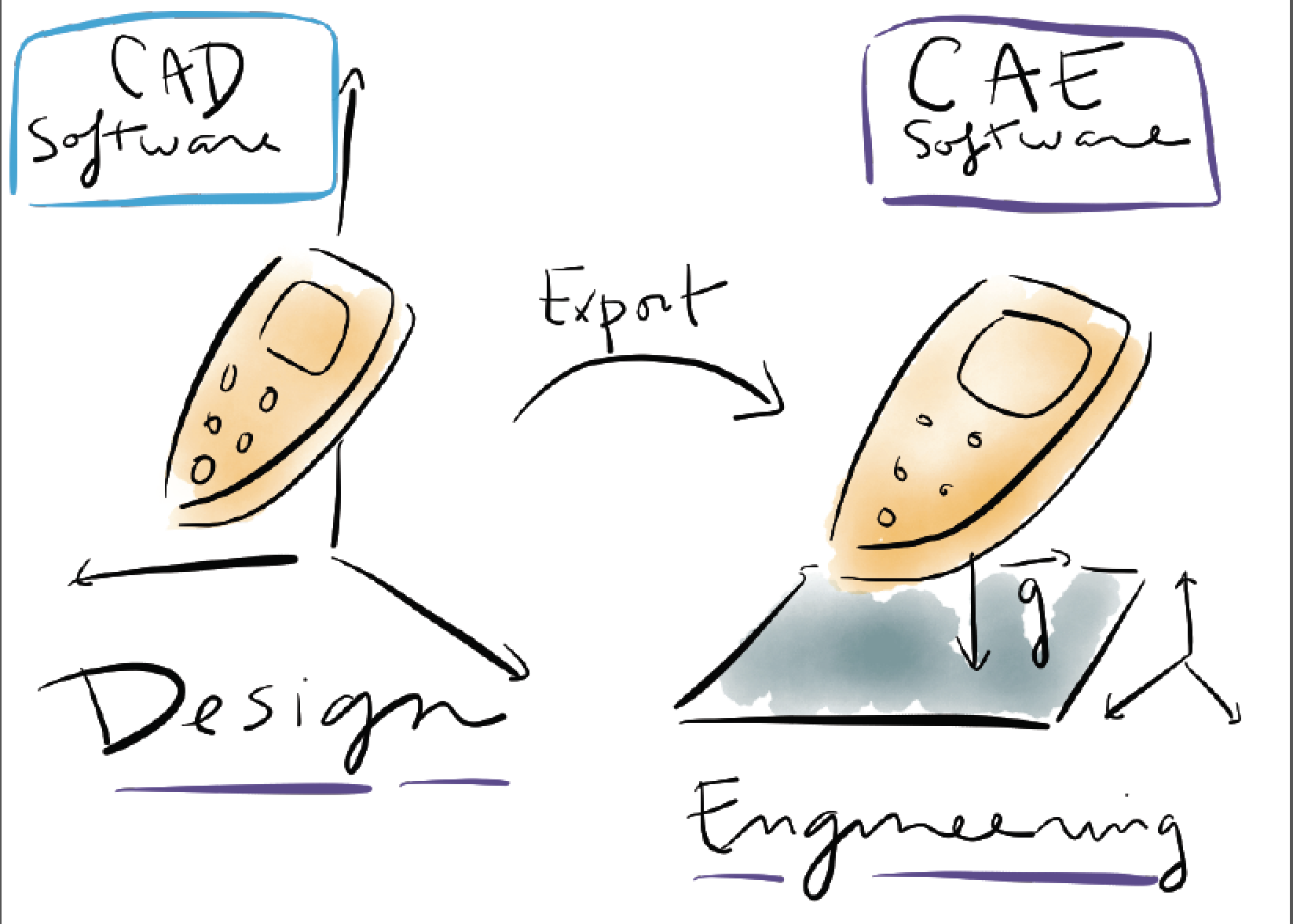

CAD is about creation/generation of the 3D model (Design). CAE is about testing its characteristics (Material, Strength, Fatigue…) using engineering methods.

The biggest mistake that the people who are not specialists are doing, is to believe that CAE is a kind of continuum of CAD. Their thoughts are in fact quite simple. CAD is 3D model creation and CAE is the Analysis of a 3D model, so CAE is the continuity of CAD (sic). The problem is that it is not so simple.

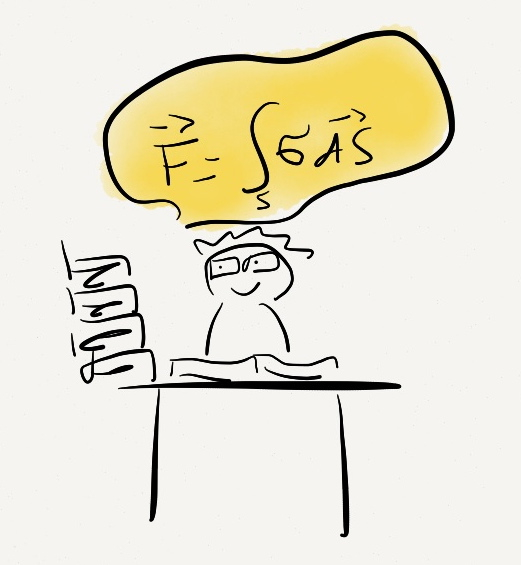

To create a 3D model in CAD, you only need some basic technical skills (how to create a plane, how to extrude, where to place a hole…), everyone who has a bit sense of 3D geometry in space can do it, but for CAE you need to have a real engineering background about a lot of engineering subjects.

Just to cite some useful areas of knowledge for the CAE engineer:

– Basic Mechanics

– Continuum Solid Mechanics

– Resistance of Materials

– Science of Materials

– Fluid Mechanics

– etc. …

To get accurate results in CAE, you need to know the physics behind all what you are doing. If you are trying to get the stress in a plate, but you don’t even know what is the « Stress » and its definition, it won’t work…

Besides that, there is another problem. CAD designers tend toward the graphic perfection, the smallest details are important to give the best visual result.

Well, this is exactly the opposite in CAE engineering. What the engineer wants is to solve a « physical » problem based on equations and the best way to do that is to simplify the problem as much as you can. Why? Because it is easier to get results on something simple, because you can test it, you can make some hand calculations to see if it works.

Due to that, CAD user who wants to perform CAE analysis will always try to use the most « perfect » model (in the visual sense) to do his simulation. So what happens? If he is lucky and if the software he uses is powerful enough, he will get something obviously, but what? And how to use and verify these results (which are probably wrong) afterwards? This is the entire problem.

So for CAD users who want to try CAE simulation, what advice can I give?

– Read first a simple book about mechanics to understand basic concepts (Stress, Strain, deformations, material curve, factor of safety, moment, force, pressure…)

– Begin slowly to familiarize yourself with verify simple types of analysis on which you have the theoretical solution (the plate with a hole for example)

– Download and install FEA software that is easy to use, but with enough advanced features at the same time.

– Begin with Linear Static Analysis, which is the analysis type the most easy to understand (but be careful to learn about all the hypothesis)

In the next articles of this blog, I will explain more in details about FEA analysis theory and all types of specific Analysis.

If you like this article, let me a comment in the section below! Don’t forget to share it with your friends on social networks too :)

Thanks for reading!

–Cyprien

If you are a beginner in FEA simulation, read this article.

c’est vraiment intéressent j’ai appris beaucoup de chose de ce blog.

merci Monsieur et bonne continuation.

Merci Idrissi et tant mieux si tu as appris des choses !

je vais essayer d’ecrire plus souvent

A t’on besoin de maîtriser les théorie de maths analytique pour exceller dans le domaine ?

Bonjour Lacina,

Non, pas besoin, en general le logiciel s’occupe des equations ;)

Bien sur c’est toujours mieux de savoir quelles equations sont derrieres tout cela (c’est generalement indique dans le manuel du logiciel) mais c’est le travail du logiciel de les resoudre.

Evidemment, cela ne veut pas dire que l’on peut definir n’importe comment les conditions aux limites et les charges…

Outstanding way of putting forth the difference between CAD and CAE. Thanks.

This explanation has a pictorial impact on mind to understand the difference between cad &cae..

thnks…

I completely agree with you ! thank you very much for this explanation, it was a pleasure !

Hope that you’ll come up with some others in the future.

Thank you.

What would you suggest as a “simple book about mechanics”?

Hi,

there are a lot of books available on Amazon

Depends on the topic you are interested in particular

you can read the comments and you will know if this book is good or not… hope it helps !

So…. no suggestions.

if you search a book about FEA Analysis, I recommend this one which is very good: http://www.amazon.com/Building-Better-Products-Element-Analysis/dp/156690160X/ref=sr_1_24?ie=UTF8&qid=1423883471&sr=8-24&keywords=fea+analysis

Dear Mr. Cyprien,

At first, I am really thankful for your sharing about the difference between CAD and CAE, it’s really useful with me.

I am Mechanical Engineer as you, I started working as CAD engineer when I graduated from university 2 years ago.

And after one year I began a new my career path with CAE position. Frankly speaking, the only reason which made me change my position is that I am very interesting with simulation and that’s all. That’s why up to now, I’ve faced to many obstacle when working as CAE engineer. It’s exact what you shared in your topic.

From your article, I think I knew what I have to do to get better and I will read all articles in your blog for sure.

Once again, thank you so much.

I am also a mechanical engginier. And i currently working as a cad engineer from last 2 year but now i want to go i simulation and fea.

Can u plzz tell how i jump as cae engineer from a cad engineer.

Bonjour Cyprien,

Je suis débutante dans le domaine et je me trouve des fois perdu dans les informations ce qui va me servir et ce qui va pas et puisque je fasse ma thèse la dessus je dois bosser le plutôt possible et de même avoir le bon bagage.merci beaucoup pour l’explication, ça aide énormément.

Generally an each engineer for what purpose to learn CAE and how they understood the concept of CAE in simple terms can explain me sir

Thank you sir for this article….and it very helpful for interview purpose. Thank you

Hello Cyprien,

First of all thank you for this wonderful article.I love the way you are putting information in a way that even the person not having any Engineering background can understand your article.

This article is very helpful for me as I am pursuing my internship in CAE(Crash analysis) field.

Looking forward for more such article

Thank You

Very iteresting tips. Thanks indeed.

Much needed article..

Thanks.

I really admired the way you are explained sir, i should say heartful thanks to you sir….but sir how can analyse the simple stresses easily i couldn’t understand even…can you please help me sir

THANK YOU VERY MUCH SIR

Really useful tips! I haven’t even thought that there are so many fine points to pay attention to!

thanks for sharing informative article with me!

thanks for sharing article on Analyze the Fluid Flow inside a Choke Valve

helpful article for freshers!

Merci beaucoup Cyprien pour tes efforts, ça m’a été très utile .

Excellent guideline document and well pitched for the intended audience.

I often work with CAD designers and to some extend junior engineers who don’t understand the fundamental differences between the CAD definition and what CAE actually is.

As you state in your guide … they look the same. But what lies beneath the visual representation is the physical description of the real world physics, which is what CAE is all about.

Thanks very much. I am really interested in fea analysis, fortunately i am mechanical engineer. I am Nastran in cad User.

Best rgds.

Welcome to the blog Emmanuel! Don’t hesitate to ask questions on the articles, I am always glad to answer (when I can ;-) )

dear sir ,

Shall every CAE engineer must be thorough with Engineering mechanics ?if so what all topics one should cover predominantly

Count me in.

Hi Cyprien!

Thank you for the article. You have pointed well the difference between CAD and CAE.

The only thing here is at my opinion, that person who is just drawing lines and extruding bosses in a CAD system is not an engineer. Maximum a draftsman. Engineers before designing anything have at least some sense what they are doing, and can visualize how the part and/or assembly will work and behave. For me FEA is a validation tool which is accelerating the process of design and also helps reduce prototype creation and testing. A huge savings in product development costs! But still no one has cancelled real life testing)))

Otherwise all information in the article is great! especially the part of breakdown of reading and information processing))).

While technologies such as computer-aided design (CAD) benefit considerably from modern enhancements to software and engineering:- CAD is for designing a product and CAE is for testing and simulating it.

The ideal scheme:

“skeletal model CAD – CAE – designer model on the skelet (CAD)” .

But in real life, this never happens, and it turns out the opposite:

“designer model CAD – skeletal model CAD – CAE – modify designer model (CAD) …”

. . . and so many times

which is better according to your point of view

Easier way .You put in Simple words

I would love to learn the complete FEA involvinf Static , Dynamic analysis from basic from you Cyprien .

Merci beaucoup Cyprien.

I totally agree with you when you mentioned that “To get accurate results in CAE,

you need to know the physics behind all what you are doing”. And I tried to really

understand the theory, formulas and the logic since I am also a software developer

for in-house simulation program.

Thanks for your comment Liza and welcome on the blog!

Hi Cyprien

Thank you for your sincere interest in the student! My problem is a series of several thermal (simple?) FEA problems. I am building a small Blackbody furnace (reactor).

Initial FEA Model: The “simplified-discussion-vessel” will be a water jacketed round steel pipe interior 90 cm long x 60 cm diameter, sealed at each end. The vessel will have an interior “inner cylindrical insulator sleeve” 5cm thick x 50 cm long (uniform thickness). The inner sleeve will have a sealed round insulator top-hat and bottom-hat also with 5cm of interior insulation. The vessel’s top, bottom and sides will be water jacketed.

The interior will be electrically heated to 4000F. The heat loss to the water cooling jacket when idling will be <10kw-hr.

Prove: This mini reactor design is feasible. (Note: The heat loss is true because the vessel I worked on many decades ago was larger and could idle with this water jacket loss all day long . I know because I did the instrumentation, data collection, data reduction for the reactor experiments . . . The calculations and energy balance results were triple checked . . . by both Harvard and Caltech PhDs.)

I should be able to easily answer: What are the thermal properties of the insulator? I should be able to specify them to the manufacture?

Its like a 4000F 90x60cm Thermos bottle!

My question for you: In your estimation, have I completely defined the thermal problem? Is it simple enough to model, hence start looking for the correct modeling tools?

Or have I defined something horrendously difficult?

Merci

Carl

Hi Carl,

Nothing that sounds difficult.

This will be a simple thermal simulation.

You just need to have the correct material thermal properties, a 3D CAD model and a CAE software that allows you to do such thermal simulations!

I would like know sir is FEA a part of CAE ,

And do engineering calculation can be carried out through FEA software

Hi Cyprien,

Very nice article or introduction (hopefully more will come).

I like your explanation of the difference between a designer (CAD) and an engineer (CAE).

Both are engineers, but at different levels of development.

For me, CAD is a deterministic approach and in real life nothing is deterministic.

Realizing this, it is not a problem to use “simplification” and “no perfect” models to understand the problem and the designer.

Unfortunately, after many years of work, some engineers still do not reach the level of probabilistic thinking.

I am positively surprised by your explanations and engineering view because you look very young in the photo.

I wish you all the best and a lot of success in your career.

Thanks,

Damir

Hi Damir,

Maybe I should update my photos haha… Some of them have probably been taken 10 years ago

Nicely written!