If you are a beginner in FE (Finite Element) Analysis, this post should put some light on some of the most essential aspects to understand about “linear static analysis”

First of all a little of background about Finite Element Analysis for those who really start out…

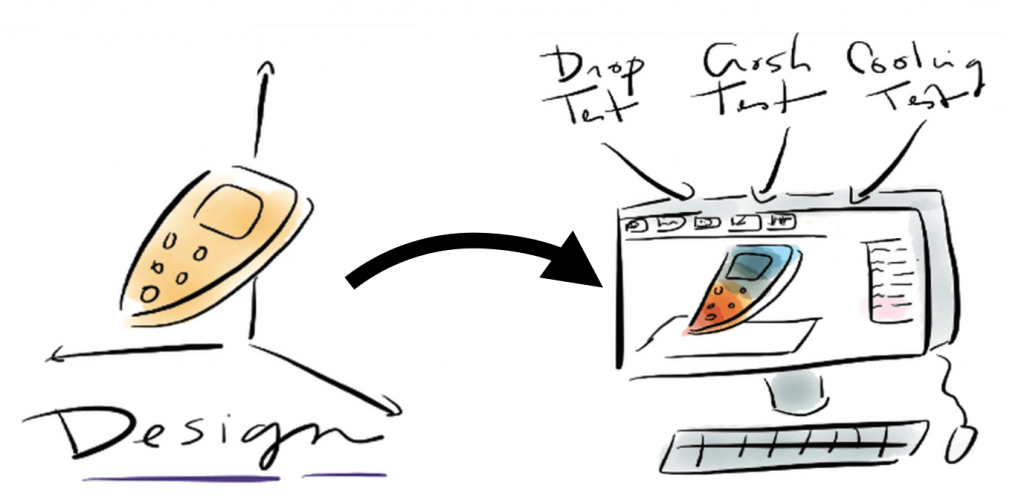

Finite Element analysis is a method that helps to simulate mechanical parts and systems to get informations about failure, deformation and stresses under some various kind of loadings.

FEA can help you basically:

– Mechanical designers to create more robust and better products

– Detect the causes of failure in a mechanical system

– Make a system safer by evaluating the risks of failure under various kind of loadings

To apply the FEA method, you need basically 3 things:

– A mechanical problem to solve and eventually a 3D CAD representation of it

– An FEA software that will help you to model and solve the problem

– Your engineering skills and experience to assess the results and improve the model

If you don’t understand the difference between CAD and CAE (FEA included), here’s an article you might like:

Article: The difference between CAD and CAE

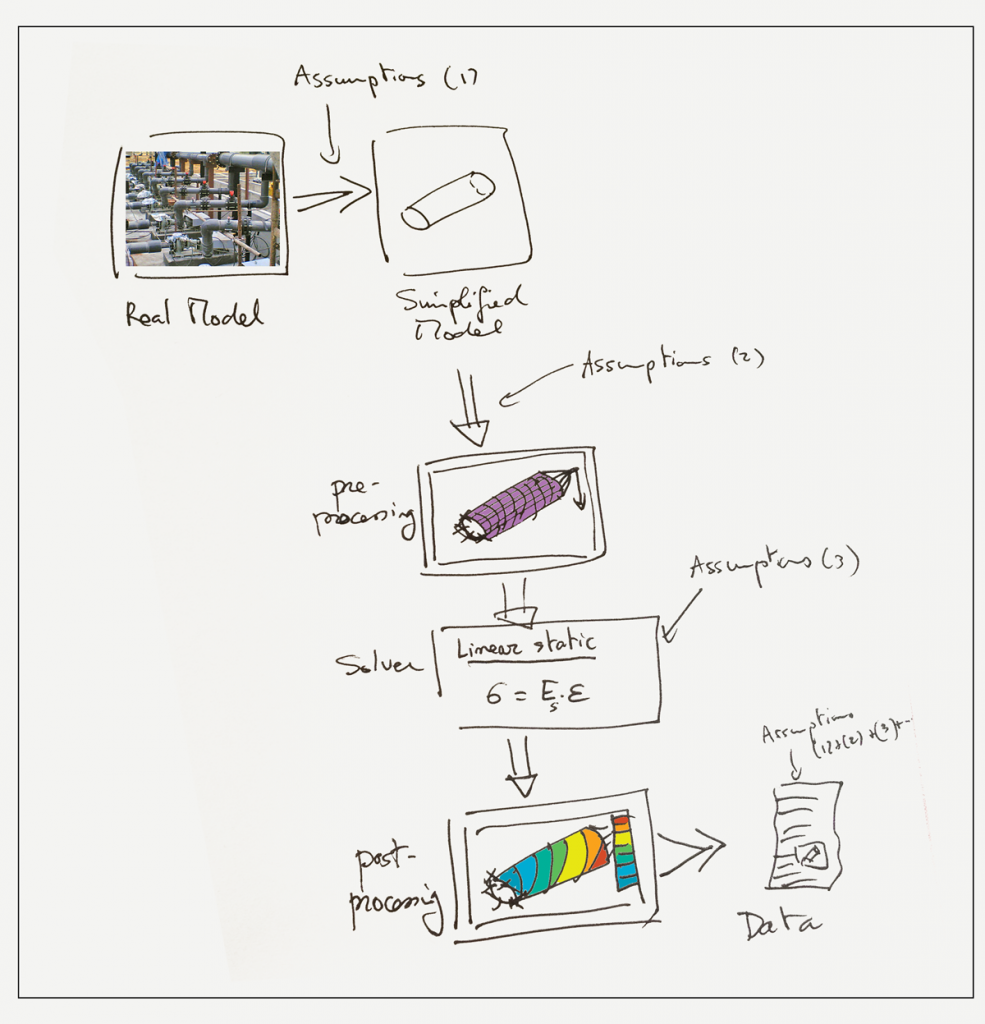

The FEA system is generally composed of 3 simple steps:

1- Defining the problem and creating the model (That’s called pre-processing)

2- Solving the problem (That’s the solver enters in action)

3- Analysing the results (That’s called the post-processing)

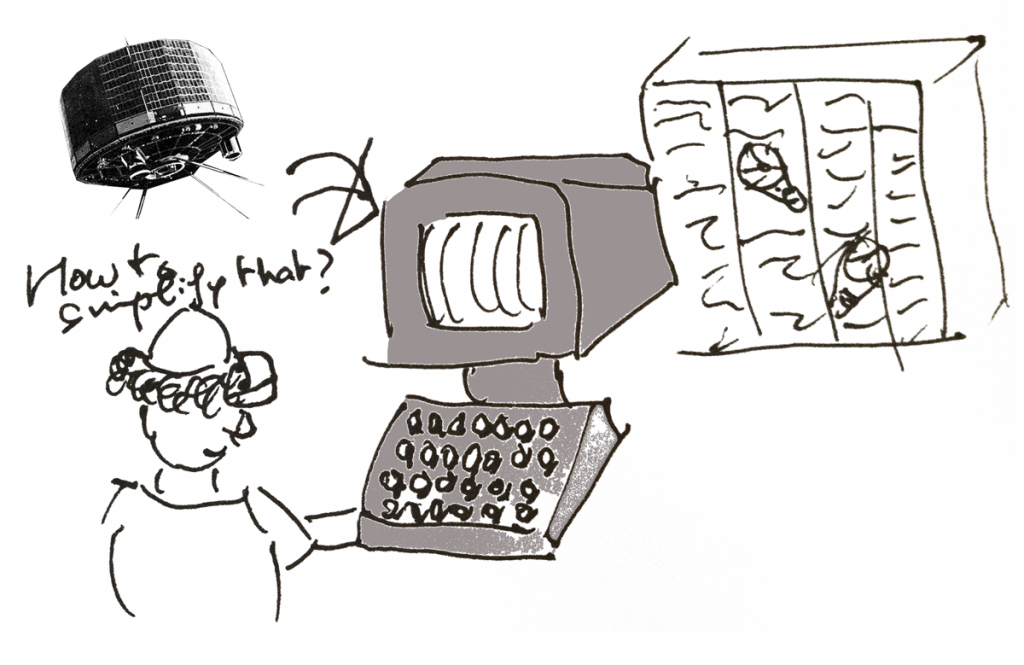

FEA simulation is also very dependent on the skills of the engineer that is using it, because assumptions have to be made all along the way from modelling to the solution and results.

Want to understand the FEA System more in details and how it works? Click here

In this article, I will be talking about one of the most capital steps required when you actually define the problem you are gonna solve:

Choosing to solve your model with linear static analysis…or deciding it is not appropriate and that you have to look further.

1- Why is linear static analysis so important?

To answer this question, I think that we have to come back to the beginning of FEA in the mid-sixties

FEA was developed by the NASA at the beginning to verify the design of costly aerospace mechanical systems (rockets, satellites, shuttle,…), because you see, when you have such a product to design, you don’t want to waste money making too many costly prototypes… you have to increase the chances of success the maximum you can before actually trying in the real world (we all know how costly were the accidents that happened in aerospace due to bad engineering…).

Additional reading: The Space Shuttle Challenger Disaster

When computer appeared to be able to do such calculations instead of us, scientists immediately seized the occasion to use it to calculate the possibilities of failure.

The only problem is that when the finite element method was first invented, the resources required to solve nonlinear very complex problems where much more limited than now.

People decided to make assumptions and decrease the level of complexity of the equations to solve to make it manageable.

Moreover, if you can simplify something and that the error can be controlled, I think also that this is the right way to go.

The first type of analysis invented, and the first type of analysis still used nowadays is « linear static analysis » . I don’t know the precise statistics, but I heard that 90% of the analysis performed are linear static… (whether appropriate or not…)

2- What is linear static analysis?

Here we comes to the main topic of this article… what is linear static analysis?

I think that the answer is pretty straightforward.

And when I am going to tell it to you, you will probably remember that for life.

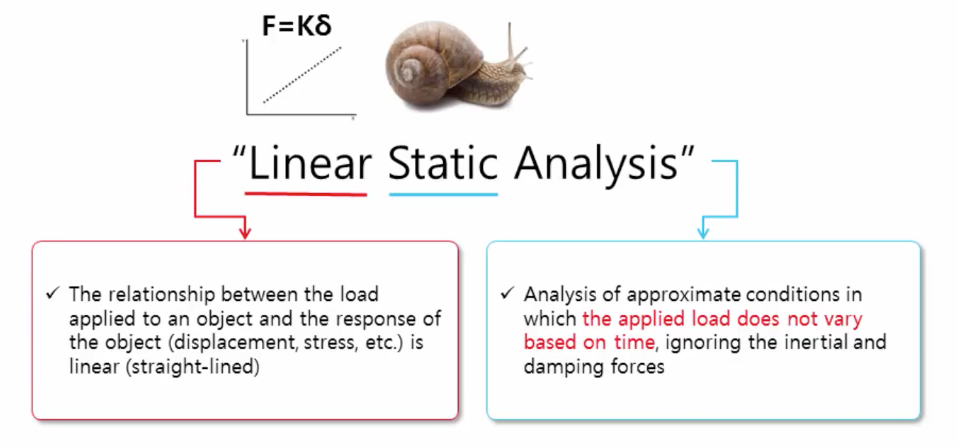

Linear static analysis is simply an analysis that has 2 main assumptions:

– This analysis is linear, which means several important things that I will discuss right after.

– This analysis is static, which means that it doesn’t depend on time.

Linearity means a lot of things and comes from the basic hypothesis that are done at the beginning:

– We stay always in small deformations

– The loads and constraints don’t change value or direction

– The material is considered elastic

It implies that:

– The equation that defines the relation between loads and displacements is linear (This relation is called the Hooke’s law)

– Increasing the loading by a certain factor will result in increasing the displacements but a similar factor

– The combination of A load and B load is equal to the A load induced displacement and the B load induced displacement

By the way, if you are interested, I have a free course that will give you more details:

[optin-monster-shortcode id=”jbivkfeiwg3prrov“]

3- How does the solver uses linear static analysis to solve your FEA problem?

Warning: that’s a very simplified explanation so you understand the concept behind all that… it doesn’t replace a real course about the finite element method…

The algorithm the solver uses to solve linear static analysis is very simple.

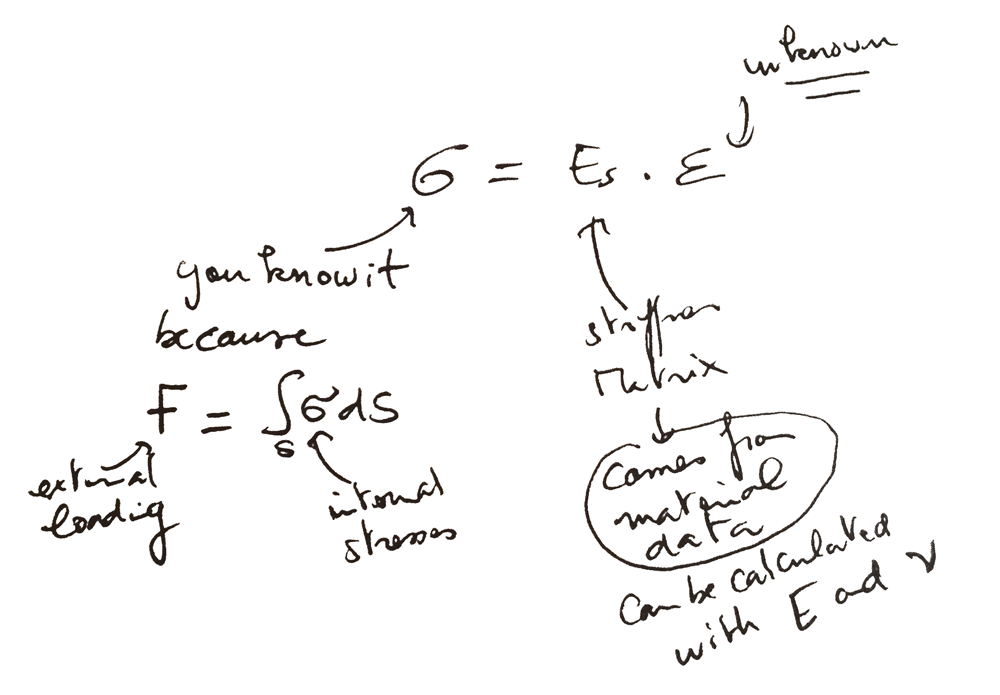

What it basically has to do is to solve a system of linear equations coming from the simplification of the Hooke’s law.

You provide the loading data, the constraints, the geometry and the material data. Using this info, the solver computes the stiffness matrix and generate the boundary condition scheme that will help him to solve the system.

The unknown is the strain, which gives the displacements in your model, once integrated.

As the system is linear, what the algorithm basically does is:

1- An inversion of the stiffness matrix using a numerical method such as the LU decomposition, the Gauss-Seidel method or the Jacobi iteration.

2- A multiplication with the stress vectors to get the strain vectors everywhere in your model

3- An integration to get displacements

4- An interpolation to get stresses in your model

4- An example of Linear static analysis

That’s actually a fairly old video tutorial I did some years ago, but I think it is still interesting for FEA beginners to understand a simple linear static analysis workflow:

Ok, that’s all for today

//////////////////////////////////////////////////////////////////

I really want to contribute and help engineers (and students) who are new to FEA to understand basic concepts better and faster!

I am not hiding that it takes a lot of efforts to write all that, so…

If you like this article, there are 3 things you can do for me:

1- Help me to share this article on Linkedin, facebook, twitter or in your habitual forum to help more people understand those basic concepts better.

2- Let me know in the comments what you learned from it and what you would like to learn even further so I can write more on the topic.

3- Join the newsletter and I’ll send you everything I write (and much more) by email!

Thank you for reading!

–Cyprien

Hello, I want to thank you for this article it is very beneficial for me. I don’t know how to Join the newsletter??

Really Nice read..appreciate it.

It’s nice and simple article and give overview for FEA. Hope that you can contribute more valuable writing like this one.

Can safety factors be used when looking at temperatures of a component?

Say I had 3 materials to choose from that I could manufacture a component from and they all have different melting temperatures A) 400 B) 350 C) 310 the max temp the component will reach is 300 Fahrenheit . Could I be given a safety factor that my component has to meet and use this to decide which material to use?

This so good . I want to say when i start reading your article each and every line i got knowledge from them. Your writing skills is so fluent and basic terminology that you used for exaplin this its really outstanding .

Thank you Harish! Glad you like the reading :)

if I give initial condition for temperature let say 23C

*INITIAL CONDITIONS, TYPE = TEMPERATURE

all,23.

Does that mean model is non linear model ?

what are the parameters that make the model nonlinear ?

Hey !

I have a question .

Please spare some time to resolve my query.

How stiffness is related to Young’s modulus?

As in the stress strain relation you point out the Young’s modulus as Stiffness matrix but the fundamental FEA equation is F=k*u in matrix form …where k is stiffness and u is deflection (linear) for applied force F.

So , please clarify the relations as the articles also says that Stiffness is calculated using Young’s modulus and Poisson’s ration.

Waiting for your reply.

Please clear my doubts.

Check this page:

https://en.wikiversity.org/wiki/Introduction_to_Elasticity/Constitutive_relations

Hello Cyprien,

Thank you for sharing the knowledge. I really enjoy the way you talk about FEA which is simple and comprehensible, yet very interesting.

Thanks Thang!

how to calculate the “g” value at different levels in transient analysis for a load of 50g,11ms

Each sentences are knowledgeable. The people who have gone thorough the math of all these stuffs at uni will understand how good this article is written for FEA enthusiasts

That was very helpful….. Very easy explanation thank you

Thank you for sharing knowledge

Thanks a lot for your helpful articles!