Many engineers I meet don’t know there are several failure modes…

Beam failure (not intended to be realistic ;-) )

They think:

« That’s pretty simple… you apply a load, the load is too heavy, so your system fails and breaks… »

Ok. I acknowledge that this is obvious… systems can break under a heavy loading.

In fact… even a 3 years old would understand this logic.

BUT…

That’s not all!

Don’t wait to have a big security problem in your system to finally try to understand what’s going on…

Let’s discuss together some of the major failure modes.

Just a note before starting with failure modes:

That’s a LARGE topic with an awful amount of crazy knowledge to understand.

That’s why I’ll only be mentioning the most obvious things… because my purpose is only to make you AWARE that those problems even exist

…Hoping that if you are concerned by one of these failure modes , you will do your own research to understand.

Why do you need to know about failure modes?

If you are still wondering that, here’s the most straightforward answer in the world:

You have to be able to see how a system can fail to improve it and protect it against potential failure modes.

Don’t wait for it to break down to take action.

(That’s what most companies do though… and that’s when they start to realize they might need to use FEA to find out the cause.)

What are the typical failure modes?

Let’s see that now

1) Fracture: When cracks appear

I guess that everyone saw some cracks in a bridge or in a wall… well, that’s a sign that the structure has a problem!

When a new cracks appear or existing cracks are extended, you are basically looking at a fracture mechanism.

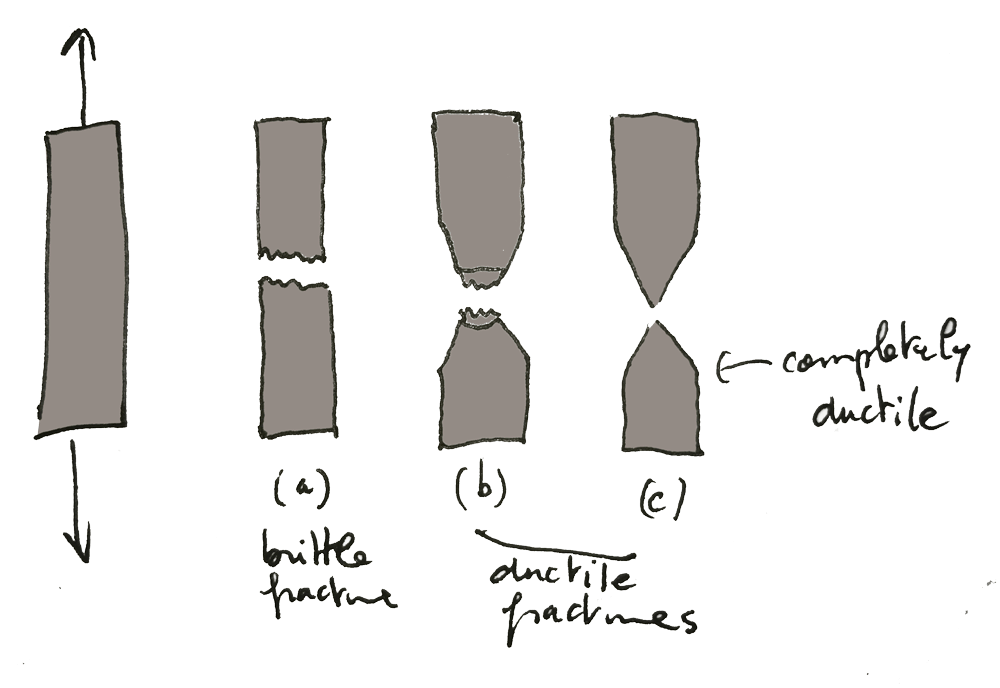

Not every part fractures in the same way:

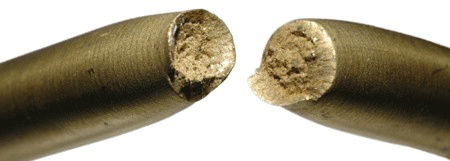

Some parts fracture slowly and deform plastically before seeing a sign of a crack… that’s because those parts are built in a ductile material.

Ductile fracture with characteristic distortion and shear lip

Steel is basically a ductile material. It extends and deforms before failing.

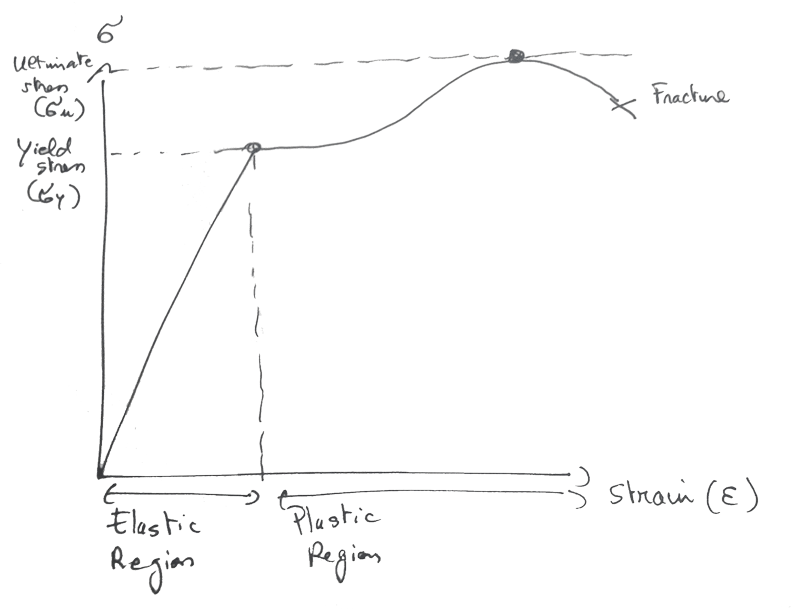

That’s why the stress-strain curve is like this:

Now… you have also brittle materials!

Those are much more « sneaky » if I dare say

Those materials tend to fail suddenly and abruptly without showing any sign of plastic deformation.

Concrete and glass are 2 examples of brittle materials.

Note that you have also materials which a ductile up to a point and then become brittle.

Some materials like bone can be ductile or brittle in function of the strain rate ( Source)

Here’s a picture that shows the difference between brittle, ductile and semi-ductile materials:

Want to see how a real beam fractures?

Watch this video (you can skip just to watch the interesting moments):

How do you simulate fracture with FEA?

Well, that’s a difficult topic so I won’t talk about it now, but that’s really something that deserves your attention to study.

You will find fascinating theories and algorithms to solve fracture problems… a lot of them being still very experimental.

(If you have something to add to that or experience with fracture simulation, please write it in the comment section, that will be useful for everyone reading)

2) Yielding: When a body experience stresses

Yielding is probably the most common type of failure analyzed with FEA

It describes a body which experiences stress in excess of the yield stress.

Yielding is only called yielding when it actually compromises the integrity or function of the part that yields.

Why do I need to precise that?

Sometimes you may observe a « localized » yielding that cause strains near stresses concentrations in your part, but then… the stress in redistributed and the yielding actually stops.

How to simulate that with FEA?

The most simple type of analysis, the « linear static » analysis, deals with this kind of failure mode.

Nothing too complex, just normal FEA… and a lot of engineering judgment.

3) Insufficient Stiffness (Deflection): When flexibility causes failure

Whatever the mechanical system you build, it must be stiff enough to resist the loads.

Seems pretty basic, but that’s really a notion at the heart of mechanical engineering.

It was also probably one of the first lessons I learned when I used FEA for the first time in my life.

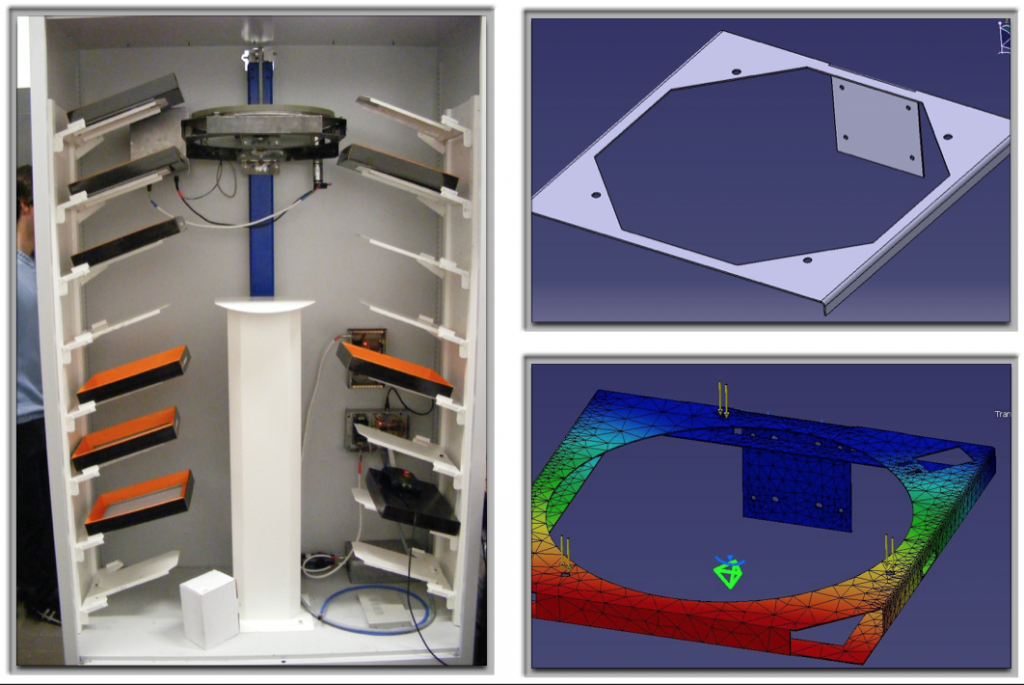

The system you see here is a mechanical system I was building for a student project when I was in the Ecole Centrale of Lille in France in 2006-2008.

If you are wondering what it was supposed to do…well, a scanner was placed at the center on a mobile platform and a rotating arm was supposed to take the sheet going out of the scanner and store it in a removable tray.

The part on the top-right picture was supposed to support a big ring of steel of 50 cm diameter and around 3 kg.

I designed it the most simple way I could at that time… a sheet of metal simply folded in 3 pounded to make a big hole.

Then when I had to BUILD this system, I realized that this part was bending with a deflection of something like 10 cm…

How I used FEA to solve the problem

The consultant supervising my team of 6 people told us something I still remember back now:

« Your part is bending because it is not stiff enough, if you fold it again a second time in other direction, it will become much more stiffer…. »

That’s when I had the (brilliant) idea to come up with a new CAD model design that would solve the problem…

I didn’t have much time because the project was due in 2 weeks… so I decided to use FEA to solve this problem (before doing the testing… gaining around 1 week of time)

I simulated the part and the FEA software told me that the maximum deflection would be 2mm … probably not the best I could get, but acceptable…

I built the new part and tested on the system…and it actually WORKED.

Man, I was stunned.

I thought to myself: « This FEA stuff is quite something, I’ll have to dive deeper into it when I get the time »

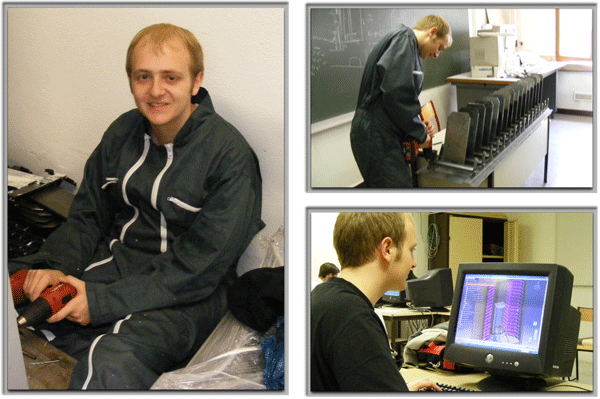

By the way, If you don’t believe that I built this system, here’s an actual proof ;-)

If someone tells me how I can get back this hair, I’ll pay you a beer! :) (Don’t tell me surgery, haha…)

Ok, I was on the road to explain you the different failure modes… back on the road

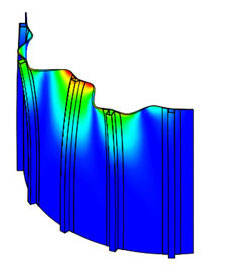

3) Buckling: When a loss of stability creates big damages…

In a nutshell, buckling a kind of failure that happens to certain types of slender geometries because of the inner instabilities that occur in the loading.

In it very dangerous because buckling failure can happen much before the material failure (Yielding).

I won’t talk too much about this failure mode because I already wrote some much more detailed article just about it here:

http://feaforall.com/buckling-simple-explanation/

Another important point about buckling is that it is not detectable in FEA if you are just performing a linear static analysis. You will have to perform an actual « buckling » analysis to see its effects (and that’s why knowing about it is important)

4) Fatigue: When time causes a loss of strength

When you hear a story in your family that they were driving the same car they drive for more than 10 years and suddenly a part failed and they didn’t know why…

That’s probably because of Fatigue!

Fatigue is a failure mode that takes a lot of time to happen.

Basically, you can understand it like that…

When you use a system, even if it is designed to be resistant enough to the loads applied to it… after some cycles of loading, the parts start to lose strength and become weaker.

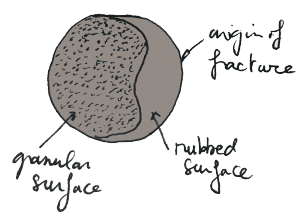

A typical fatigue failure of a part looks like that:

Part which failed due to fatigue

How do you simulate Fatigue with FEA??

I have an old guide that explains simply the principles behind Fatigue analysis.

Join my newsletter here and I’ll send it to you (along with other free material and courses)

[optin-monster-shortcode id=”aereopxpatfcxnuc”]

5) Creep: When a body deforms over time

Those analyzing concrete structures like bridges or buildings know this mode of failure very well.

Creep is simply the natural tendency of some solid materials to move slowly or deform permanently under stress.

It is increased when the materials are heated (the extreme example is when steel is melt under high heat to make it change shape)

Creep failure of a pipe

Creep is far from being negligible as it is involved in many accidents around the world.

For example, some experts say that the collapse of the world trade center was due to Creep

(Search for the word « creep » in the article to find the explanation)

How do you simulate Creep with FEA??

Creep is generally handled by a special type of material model in your FEA software and is still very experimental.

There are many different creep models available which depend on the kind of model you have.

Creep generally happen over a very long time period, thus it is very difficult to observe in reality or to make theories about it because the scientist will have to wait years before seeing results.

Same for FEA, even if you have creep models and you can theoretically simulate creep, you have to be very careful about the accuracy of those results without any experiment coming to prove that they are correct.

(If by some chance you have some experience in creep and you have something to add, please enlighten everyone by leaving a comment about your experience.)

Can several failure modes happen at the same time??

Yes, it most engineering problems, that is what happens… that’s why it’s alway important to review the data and try to spot all the possible signs of any failure.

Good luck with that!

///////////////////////////////////////////////////////////////////////////////

You maybe noticed that I wrote a lot of great educational article… that’s because I really want to contribute and help engineers who are new to FEA to understand those concepts better and faster!

I am not hiding that it takes a lot of efforts to write all that, so…

If you like this article, there are 3 things you can do for me:

1- Help me to share this article on Linkedin, Facebook, Twitter or in your habitual forum to help more people understand failure modes (use the share button on the left of the article).

2- Let me know in the comments what you learned from it and what you would like to learn even further so I can write more on the topic.

3- Join the newsletter (if you are not already subscribed), I’ll send you everything I write (and much more) by email!

Thank you for reading!

–Cyprien

Another nice article Cyprien…

Thank you very much, Angus!

good one…..

Nice Cyprien!

Thanks for sharing this knowledge!

Thank you Jose!

Great article for remember this topics!

Hi… it will helpful if you brief about the failures due to torsion.

Thanks for the article…

Great article Cyprien. I am thinking about translating your articles and incorporating them in my lectures ?

Thank you Sergey! That would be great :) I would love you to do that :-)

Sergey you will translation in to Russian?

Thanks for sharing this knowledge.

Is Vibration not a failure mode??

You can have failure due to vibration or in more general due to the dynamic aspect of the system you study, but vibration in itself is not a failure mode.

Great. However, need more technical details about Modeling of FEA.

Thanks Cyprien, after 10 years as simulation engineer within a big automotive company and 5 years as manager of a simulation group, you have have done a work I would have like to do. your scheme and article are very clear, and I use it with my simulation engineer even skilled one. I always request them to explain clearly their results to our “clients” in a simple way even if we put a lot of science our analysis and models. Thanks again for the work you share with the simulation community. Back to basics is always good.

JR

Merci beaucoup Jean-Roch! Ca me fait très plaisir que les articles que j’écris puissent servir a éduquer vos ingénieurs! La simulation de nos jours passe de plus en plus pour une sorte d'”amelioration” de la CAO et beaucoup d’ingénieurs oublient les principes important de physique et d’ingénierie qui sont derriere tout cela.

J’espère que nous resterons en contact! N’hésitez pas a me contacter par email directement si besoin est.

Thanks a lot for this training material. It really helps me a lot.

I’m responsible of the designing the truss of escalator

And I would focus on the strength, stiffness and stability of the truss.

Sometimes I would get lost why I should do this. But this time, your vivid example show me that I was doing the facsinating job, and there would be lots of interesting topics I can learn.

Again, thanks for the inspiration you gave me.

Thank you Michael for this wonderful comment! I am glad that it motivated you to understand better the systems you are working on, this is trully awesome :)

Excellent summary of a (potentially) very complex topic. I teach a module on material failure as a part of a health and safety diploma. This article has at least confirmed that my delivery of content is consistent with engineering principles.

I was wondering whether you have any specific references on pressure system failure (pipework and/or pressure vessels)?

Regards

Chris Jones

Hi Chris,

First of all thank you for coming up to my blog and getting value from the articles I write. I am glad it can help you or even complement your course in some way.

You will find here a webinar I made with a colleague some years ago about pressure vessels that should be interesting for you: http://feaforall.com/pressure-vessel-simulation-finite-element-analysis/

Thank you it is direct simple, it will help many to understand common failure types. If you add something about mechanism of failure and how to prevent their reoccurrences it will be great.

Hi, always nice with some “back to Basics” articles!

But I do think your first example (Fracture) is misleading. Concrete is indeed a brittle material, but is usually reinforced with steel bars and therefore acts ductile. The structural behavior of the concrete beam in the YouTube-link for example, experiance a ductile behavior. As stated in the video, most of the deflection occurs when the steel tendons have started yielding. It is not brittle before the tendons have lost its load bearing capacity and breaks. The concrete cracking is not a problem per sae, the beam resists a lot higher loading after the cracks take place.

So clearly explained! You made the topic simple.

Regards

Great article!

By the way, you comment section is backwards (i.e. latest comments should be on top, to add a comment should be on top as well.)

this is an excellent article which integrate several knowledge to one

Hello Cyprien,

Thank you for this wonderful explanation on failure methods. I am a Mechanical engineering graduate & like your way of explaining things.

Hi Cyprien,

Actually I have already subscribed to your newsletter! Could you please send that fatigue analysis guide as you mentioned above? That will be a big help!

sir , can u identify what kind type of failure may be on brush cutter blade??

Very nice, thank you Cyprien!

Great conceptual article CYPRIEN, I been following you for at least three years. Keep doing!!