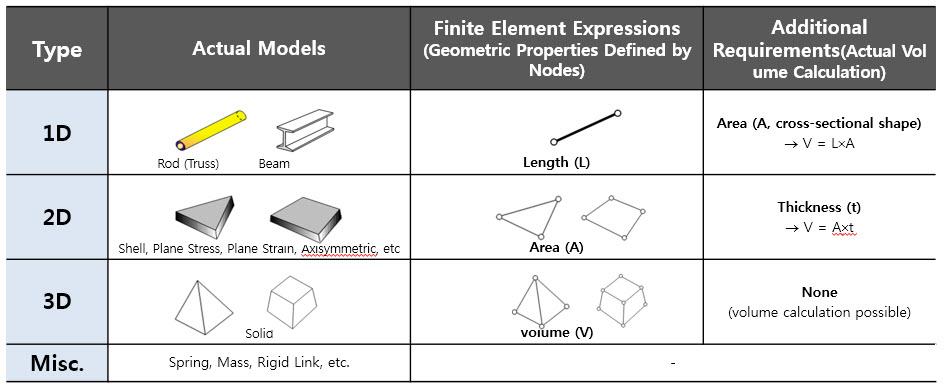

Yesterday, my Friend Apoorv Sharma conducted a webinar about FEM Modeling and the topic was quite popular as over 200 engineers registered to attend.

I suggested Apoorv to include a simple poll about 1D,2D and 3D element types to see what the engineers that joined the webinar were thinking.

If you want to watch the webinar too, you can see a replay of the webinar here:

Watch the Introduction to FEM Analysis Webinar

I will share below the results of the polls that was conducted:

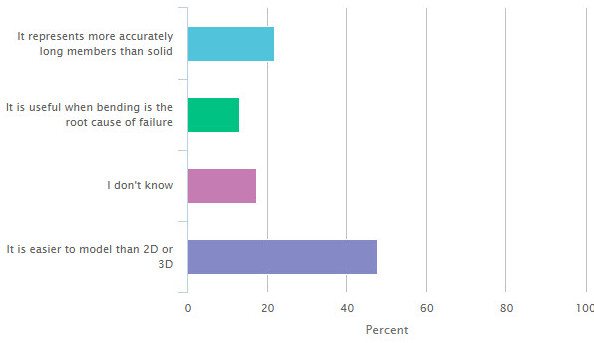

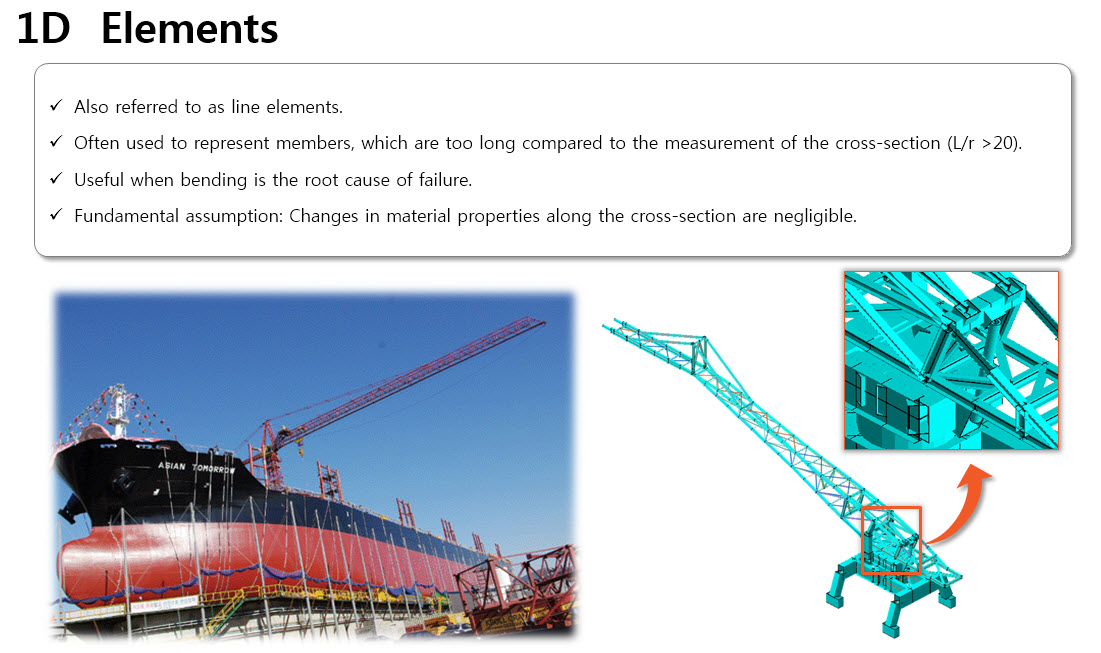

Why do FEA engineers use 1D elements ?

Answer:

There was no wrong answer to those questions, but one of the major advantages of 1D elements is that they allow to display directly the bending which is one of the root of failure in structures with long member structures.

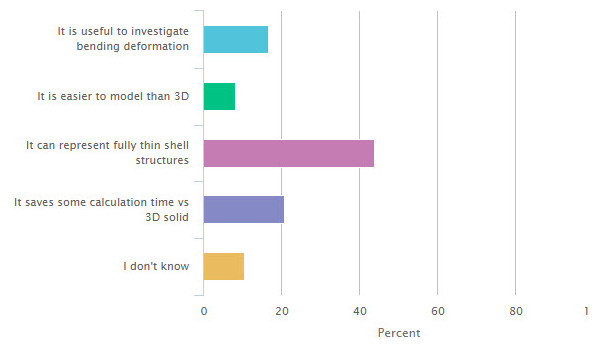

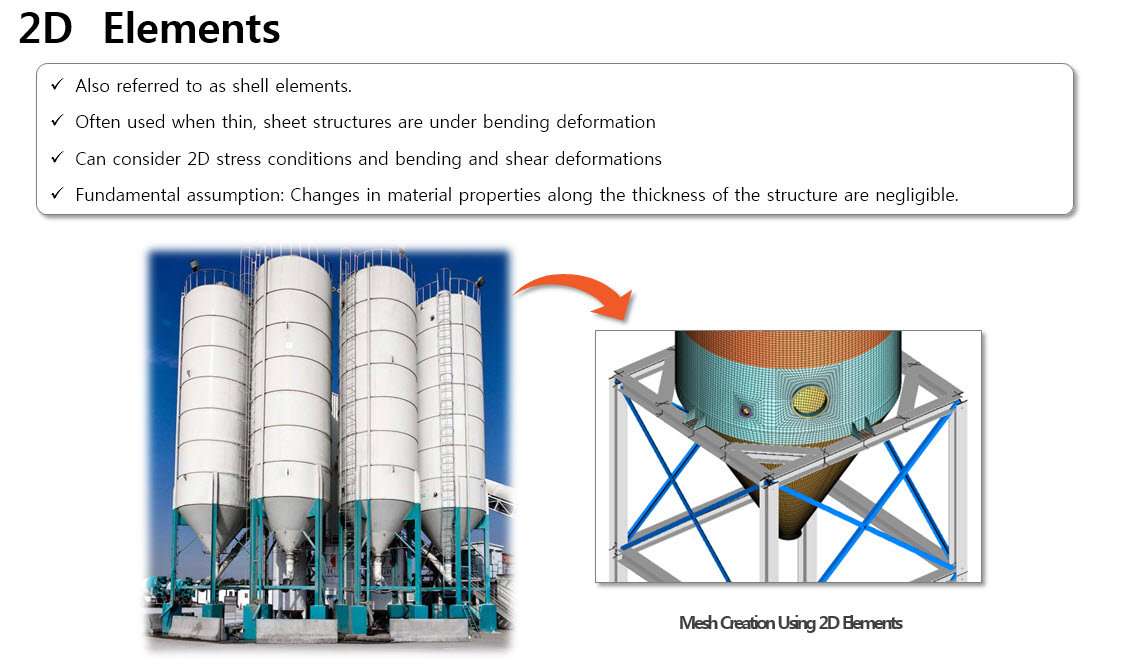

Why do FEA engineers use 2D elements ?

Answer:

In this case, the best answers were the answers 1 and 2, 2D elements are useful to investigate bending as results can be directly compared to those in the design code (when there is one). Most of the people chose the answer 3 “it can represent fully thin shell structures” which is also correct* is you consider the fact that thickness is not necessarily constant… answer 4 is obviously correct too.

*Thanks to Matt Watkins for the correction

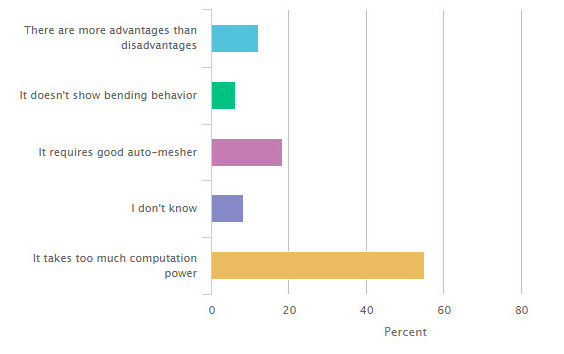

What are the main disadvantages of using 3D solid elements?

Answer:

Here, every answer is correct, but it is quite clear that people are thinking first about the computational power when using 3D solid elements, which is true ! Solid elements will give most accurate stresses in each direction, but it may requires very small mesh, which will increase the time needed for the solver to compute all this.

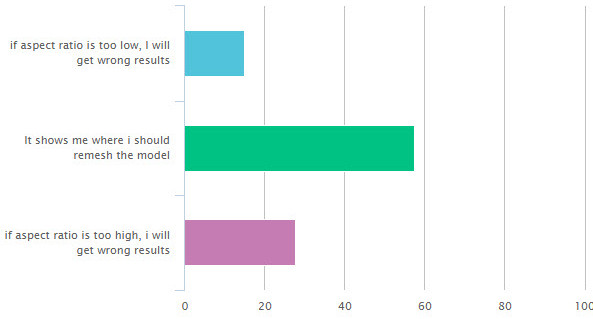

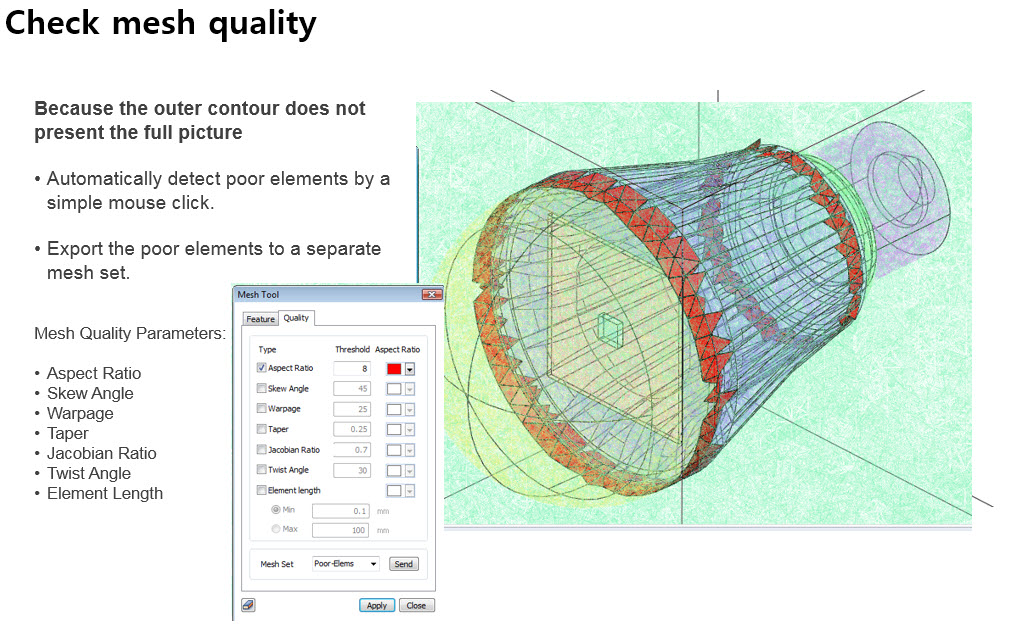

Why should we check the mesh quality ?

Answer:

Here, correct answers are 2 and 3. Aspect ratio is the ratio of the longest mesh edge divided by the shortest mesh edge, so if it is high, it basically means that the mesh element is very deformed. At the same time, if mesh quality is wrong somewhere, we have to remesh at this position to be sure we will get accurate results.

What would you have answered to those 4 questions ?

Let me know in the comment section

Here is the webinar recording:

Your answer to the 2D element question is incorrect: “as thin shell structures don’t have necessarily constant thickness”

Shell elements do not need to have constant thickness either, so problems involving thin-shelled structures can indeed be done with shell elements. No problem.

You are right, I will add your comment to the post ! Thanks for your help Matt

Thanks Cyprien! I’m going to use it to explain at my course,

You’re welcome Jesus, I am glad this article helps you.

Thanks sir

you have provided valuble information.

Regards.

Ram pawar

Thanks sir

This info is really helpful.

How can “if the aspect ratio is too high, I get wrong results” be correct, while “if the aspect ratio is too low, I get wrong results” is incorrect? The only difference between the two is point of view. For example, a slender element in one direction will just be a too rigid element in the other two directions.

may you explain the mesh quality with more examples in another article? please

well done mate

Hii Cyprien..

Can you explain me about the parameters involved in the mesh quality check individually??!