I was myself doing a lot of CAD design before and I never thought that FEA Analysis was a big deal.

This is what I thought:

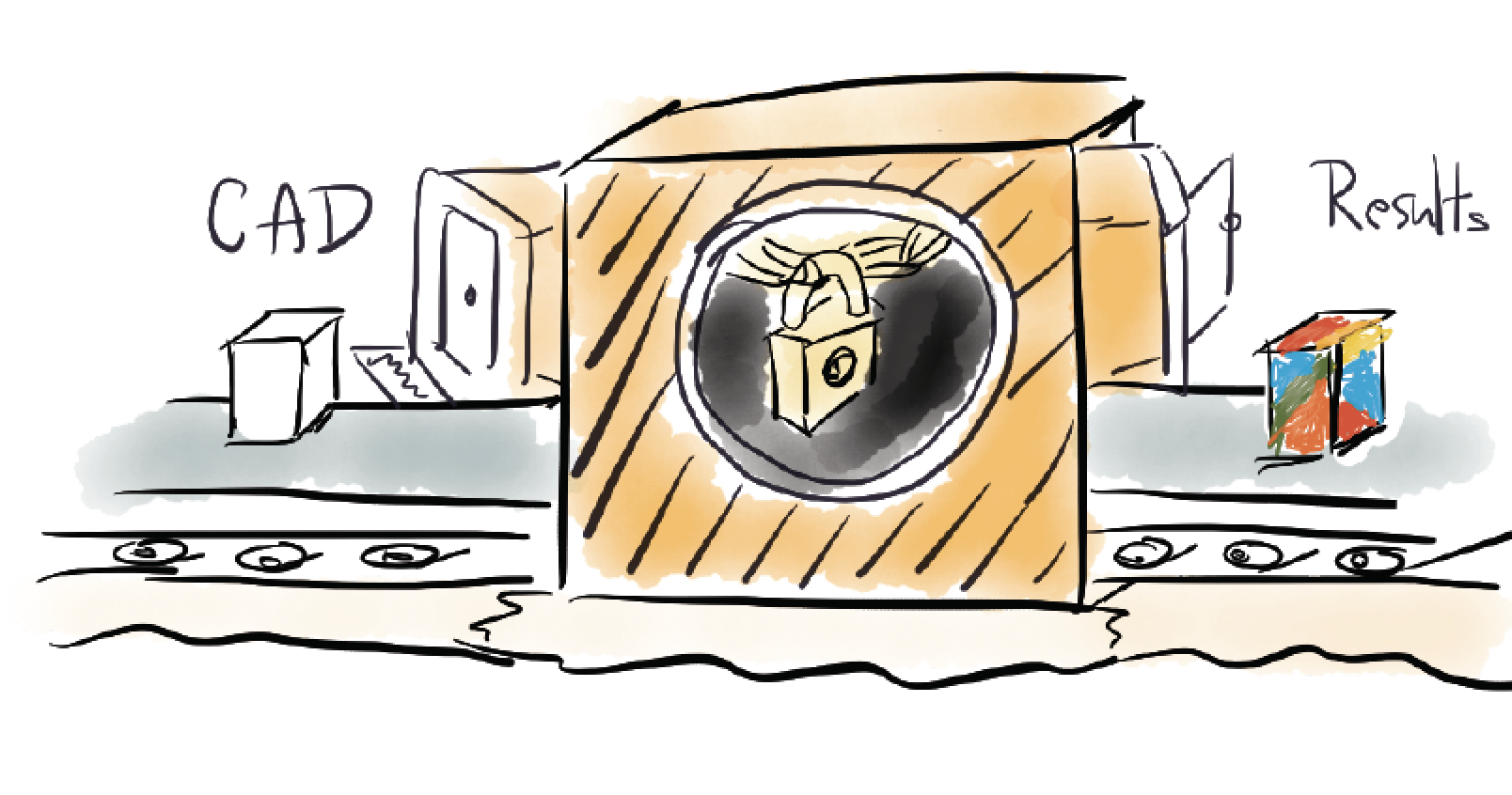

Take a CAD model, apply material, loads, boundary conditions, contacts, mesh it and then watch the results… it is like a black box.

At least it is what I thought at the moment.

But after learning more and more about FEA, i realized that FEA analysis is just a “graphical” way to apply mathematical models and realize some virtual tests on your models.

Every mathematical model has some hypothesis, so it is very important to understand in which context they can be used.

This is exactly the same for FEA analysis.

before performing analysis, you have to think a lot:

– How can model correctly my physical model in order to get reasonable results?

– What are these reasonable results and how can I verify them?

What you should do:

– Know what your are doing and what are the mathematical model behind the software (It should be in the manual).

– Never forget real experiments and your real world model!

FEA analysis will never replace completely experiments, and checking the results is a necessary step.

So (you may ask) if I still need to do experiments, why do I need FEA analysis?

To improve the process !

When you get some knowledge about your model and type of experiment and you begin to “feel” the range of results you are waiting for then you will need less testing.

But the best advantage to perform FEA analysis is that you can change the shape and design of your model at will and perform the same “virtual” experiment on it for no cost. Isn’t it a good reason to try FEA analysis ?

Don’t forget to let a comment if you have some idea on this subject, I am always happy to hear what engineers think and I will answer you for sure.

Which program do you use to make your graphics?

Hi Jose, I am using an App called “paper” on iPad to make those graphics (I suppose you are talking about the drawings, not the FEA models) ;-)

One step is make experiments and, if is possible make some hand calculations too.

Great Post! I’d just add that FEA is great when you can’t do an experiment too. I do a lot in Nuclear Power, and we can’t always do the testing. We have other methods to verify and validate the model.

But if you can test, I agree. It’s generally harder to argue with real-world test data.