I am preparing a series of articles about composite materials, I hope this will be interesting and useful :)

Let’s start with the very start… what is a composite material and where do they come from?

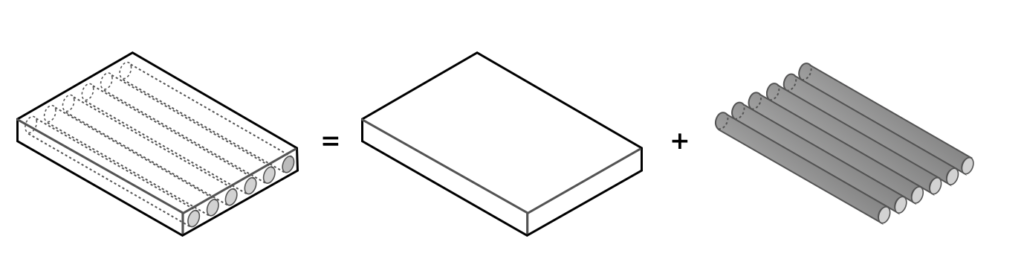

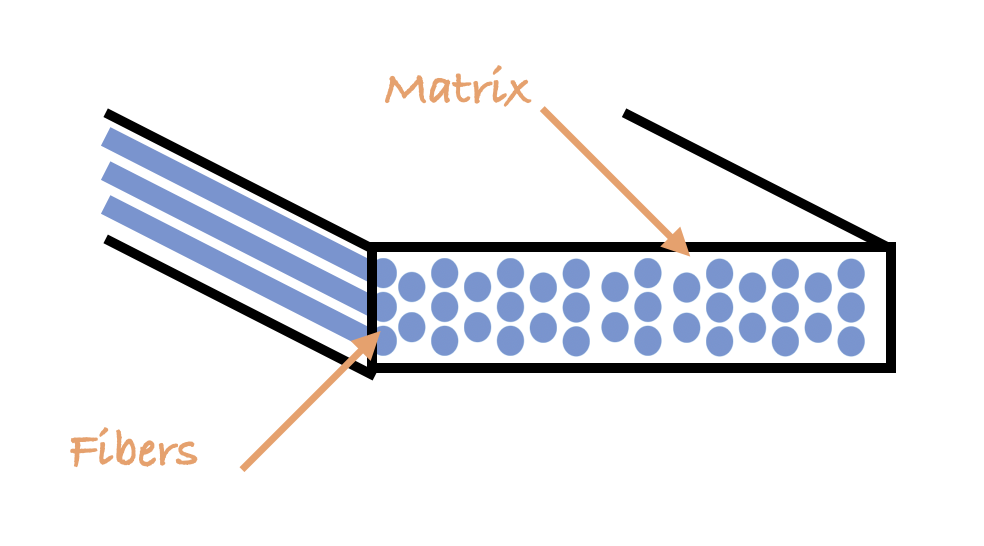

The simplest definition is that a composite is a material with 2 or more constituents

Which constituents and how are they put together? This is the most important question

3 examples of composite materials

Here you have 3 different types of composite materials to show you that the scope of those materials is wide.

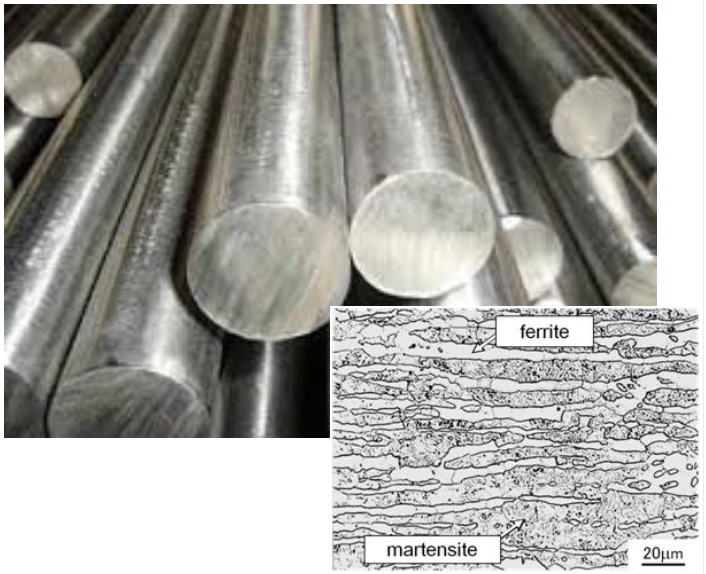

- Metal alloys which have 2 phases micro-structure

- Concrete (a distribution of aggregates in a cement matrix)

- Carbon fiber in a polymer matrix

Are Composite Materials a twentieth century creation…?

People usually think composites as engineering materials didn’t come about until the late 20th century. But, if you look at today’s reinforced plastic matrices and other great composite materials, they’re basically doing the same thing as those basic composite materials that humans have been using since we started working with structural materials.

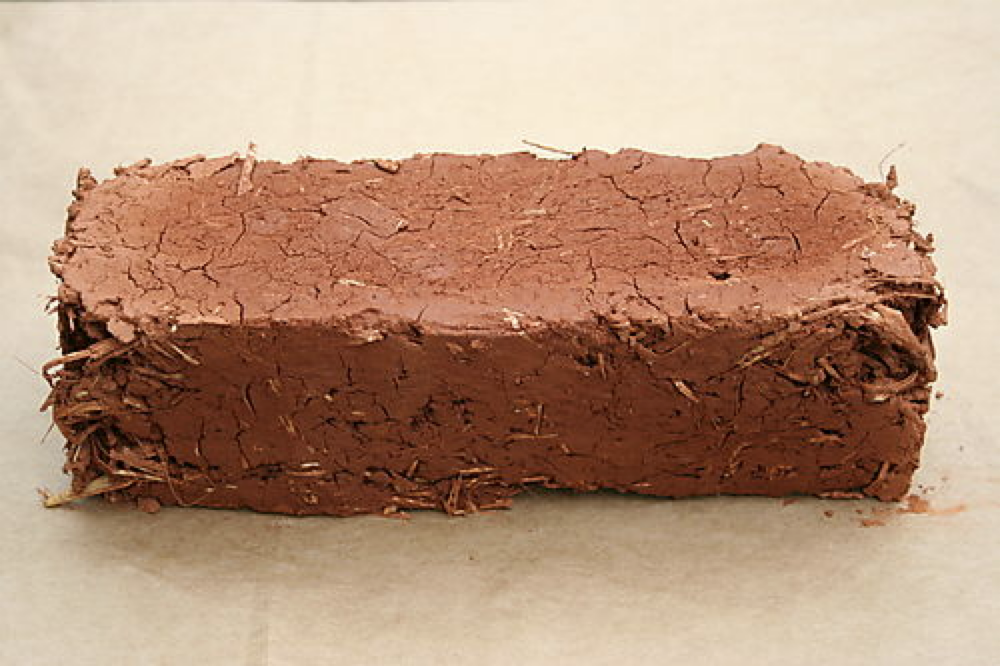

Clay bricks reinforced with straw in order to reduce shrinkage during drying and to improve their fracture toughness

Egyptians building bricks for the construction of the pyramids were already using this technique

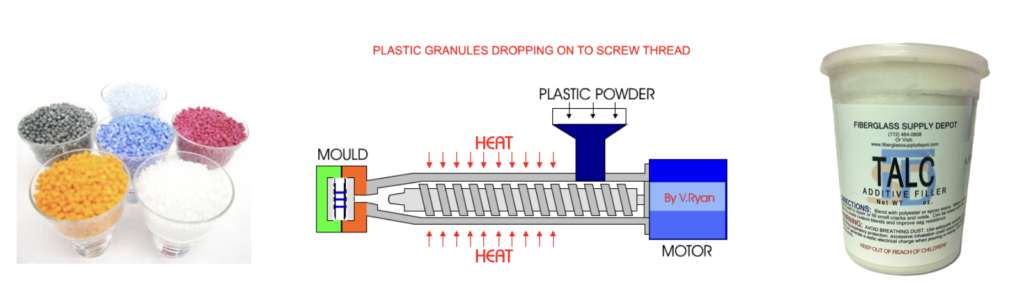

Nowadays, talc and other inorganic fillers are used in the processing of plastic moldings to reach similar aims. Even though the materials might have evolved, the fundamental process stays unchanged.

What about Natural Composites?

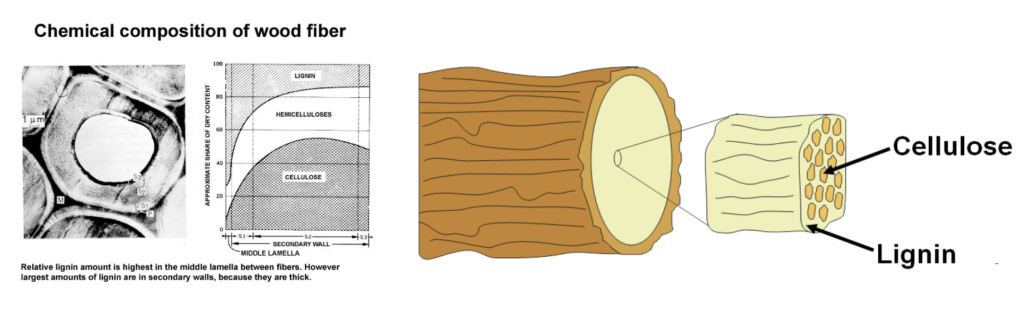

You can think of wood as a prime example of a natural composite as well – it’s a mix of cellulose fiber and lignin. The cellulose fiber provides strength, while the lignin acts like the “glue,” holding everything together and keeping the fiber steady.

Bamboo is also a wood composite structure composed of cellulose and lignin, but the difference is that it is hollow. This makes it a very light yet stiff structure. This kind of « design » is used to create fishing poles and golf clubs which need the same light but stiff structure.

A surprising composite example: The horseman bow

The large and cumbersome bows weren’t practical for horseback use. Their replacement needed to be smaller, lighter, and stiffer to maintain power, which sets design standards relevant to many modern applications utilizing composite materials.

Constructed from layers of wood, bone, and cloth stacked together, the bow formed a laminate structure. The distinct layers in the bow’s design directly relate to the primary fabrication methods employed in today’s high-performance composites.

Inspired by Nature

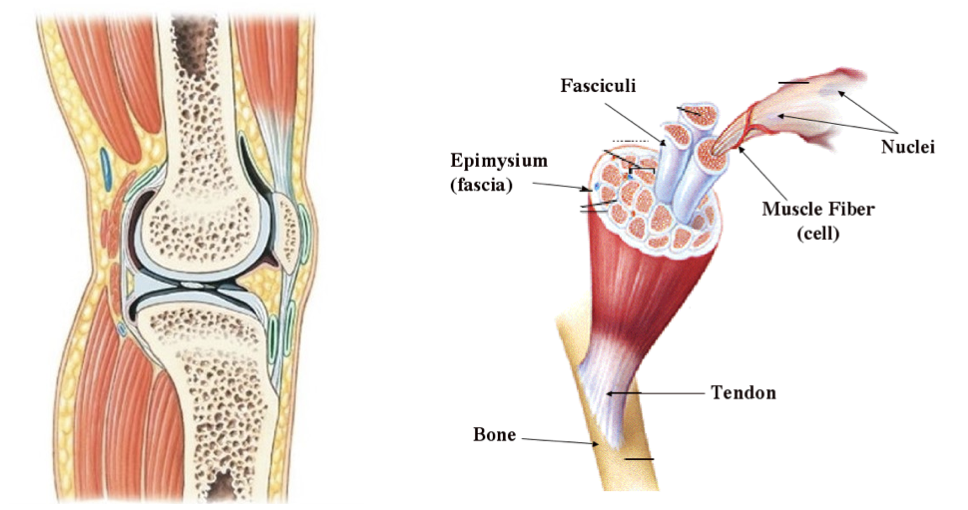

Composite materials might hold the key to many design problems humans have faced over time. But humans aren’t the only ones using combinations of different stuff. Nature also does it! From our own bones and muscles to certain types of rocks, nature combines different things to make strong structures. It’s likely humans got the idea to mix materials from watching nature.

One of the best examples is wood, which is not only the oldest but also the most commonly used structural material around. Wood gets its impressive range of mechanical properties from its cell structure, blending the strength of cellulose fibers with the flexibility of an amorphous lignin matrix. These properties enable sturdy trees to withstand extreme weather conditions, making them some of the largest land-based living structures globally.

Many applications for composite materials

The adoption of high-performance composite materials has surged since their introduction, leading to their substitution for more conventional materials in numerous applications. There are plentiful reasons behind this.

- Aerospace Industry: Composite materials are widely used in aerospace applications, including aircraft components like wings, fuselages, and tail sections. The Boeing 787 Dreamliner, for example, extensively utilizes composite materials in its construction to reduce weight and improve fuel efficiency.

- Automotive Industry: Many high-performance cars incorporate composite materials in their body panels, chassis, and interior components. Carbon fiber reinforced polymers (CFRP) are often used to reduce weight while maintaining structural integrity and safety standards.

- Marine Industry: Composite materials play a crucial role in the marine industry for building boats, yachts, and other watercraft. Fiberglass reinforced plastics (FRP) are commonly used due to their durability, corrosion resistance, and lightweight properties.

- Sports Equipment: Composite materials are prevalent in sports equipment such as tennis rackets, golf clubs, bicycle frames, and hockey sticks. Carbon fiber and fiberglass composites provide strength and stiffness while keeping the equipment lightweight and responsive.

- Infrastructure and Construction: Composite materials are increasingly used in infrastructure and construction projects for applications like bridges, building facades, and reinforcement structures. They offer high strength-to-weight ratios, corrosion resistance, and durability compared to traditional materials like steel and concrete.

That’s all what I have for today, I’ll try to write more soon about the practical aspect of using composites … and of course, how to simulate them ;-)

Cyprien “Composites Materials are cool” Rusu ;-)

Hi Cyprien,

Great article, l’m looking forward to reading the remaining series that you’re producing.

I’m also glad to see that your still here producing quality content for your blog.

FYI, I’m about to give a work presentation regards resources for open source analysis etc and I’ll be pointing many of the younger engineers to your blog & YouTube channel, so please keep up the good work, its much appreciated, even if you might not know it.

Kind Regards,

Daryn

Thank you very much Daryn!

Lately I am so busy that I have to make a real effort to continue writing.

I am glad some engineer still read and benefit from it.

Looking forward to seeing more! This is an interesting topic which generally isn’t often covered by commonly available simulation tutorials.

That is very interesting topic as I work with Composite materials 90% of time in my FE modelling (other 10% are plastics). So, I’m really waiting for the continuation and some examples, as most (if not all) Code_Aster videos about isotropic materials.

Also, any video on viscoplastisity/viscoelasticity in Code_Aster (Solome_Meca) will be appreciated.