Today’s subject: CAD model simplification for FEA analysis. Why do you need to simplify your model? How can I do that?

The most simple workflow for FEA analysis is:

1. Import CAD model

2. Mesh the model

3. Assign boundary and loads

4. Perform analysis

Unfortunately, all may not go as smoothly as we want…

– The CAD model may be extremely detailed (the dream of the CAD designer and the nightmare of the CAE Engineer), and lead to very complex or impossible meshing.

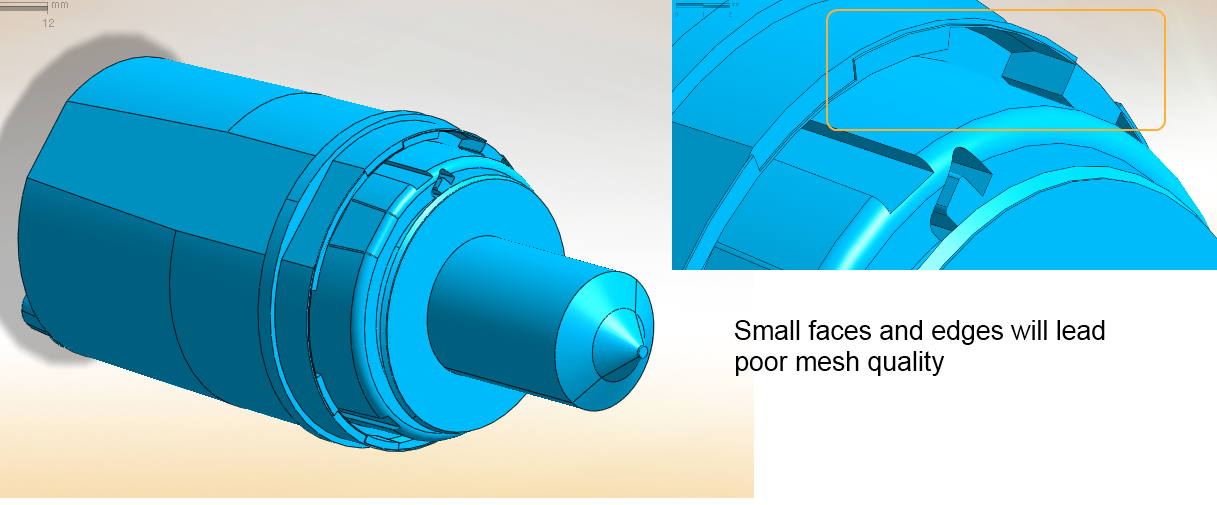

– The CAD model may contain small edges, doubled edges or very small faces which make the meshing nearly impossible.

And if you need a more deep explanation:

The CAE engineer wants to get accurate results using a solver which converge as fast as possible. Even if the relation between Mesh quality and accuracy is not as clear as we usually think ( see this blog post for more info), a poor mesh will lead to poor convergence of the solver and decrease the accuracy of the results.

Another reason to simplify the CAD model is to get a model more easy to compare with Theory, because theory always considers very simple models. If the model used from the beginning is very complex, there is no way to validate and compare results with theory.

I will give an example to explain more in details the need to simplify the model:

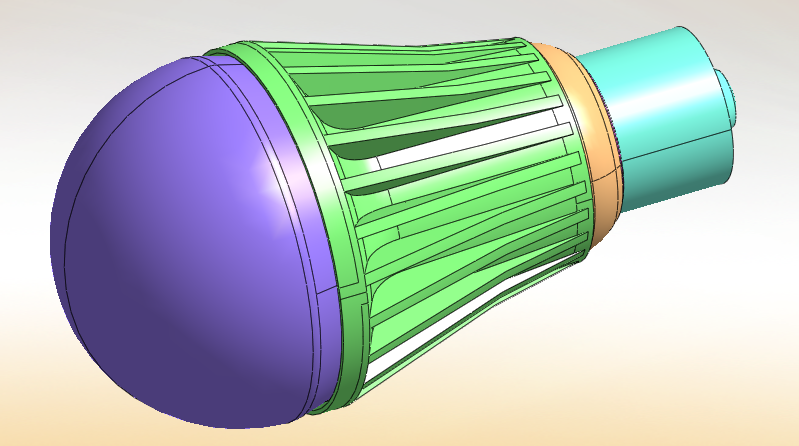

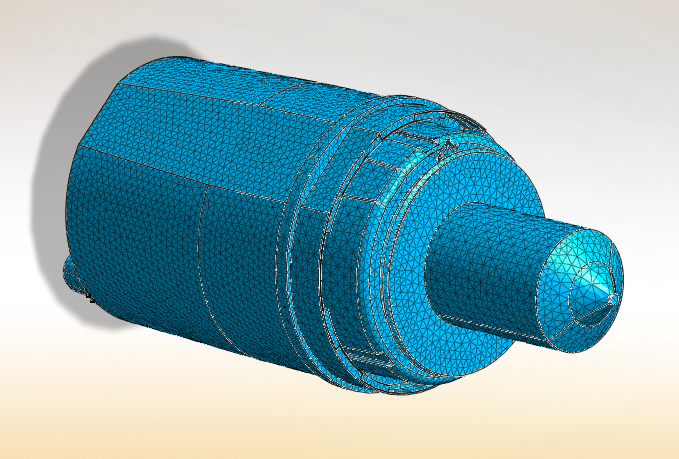

This is the CAD model of a LED lamp, and i want to perform a CFD thermal coupled analysis on it. To perform this type of analysis, I need to analyze solid parts and fluid parts together in CFD. The contact between fluid and solid is done using CFD contacts which are quite sensitive to the mesh quality.

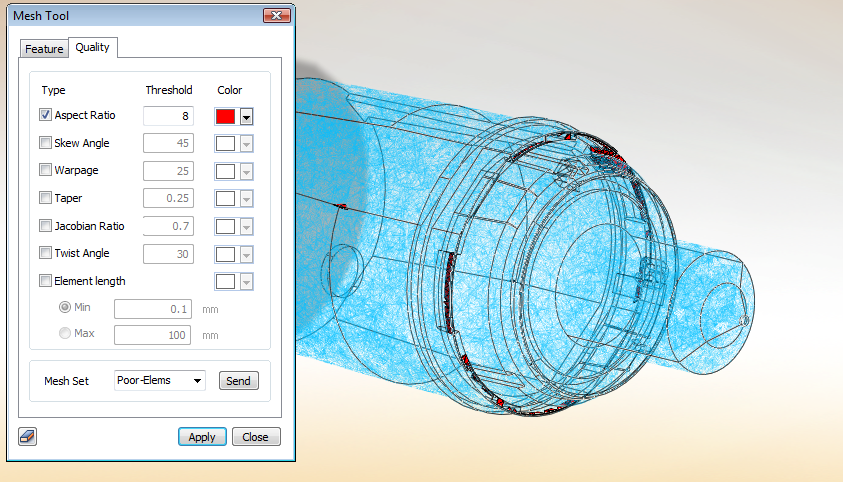

So, to perform this analysis, I need to mesh the model with very good mesh. The criteria I usually consider is the simpliest. The aspect ratio should be under 8 (aspect ratio is the ratio of the biggest edge on the largest edge of one mesh element).

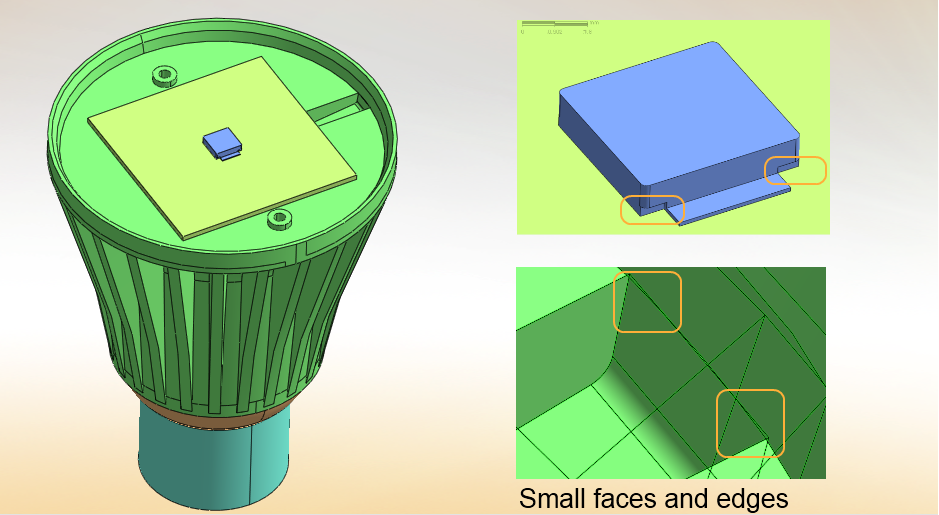

The first step is to inspect the CAD model to verify is it is “proper” or not for the FEA analysis:

After inspection, several parts contain small edges and faces which may lead to poor mesh.

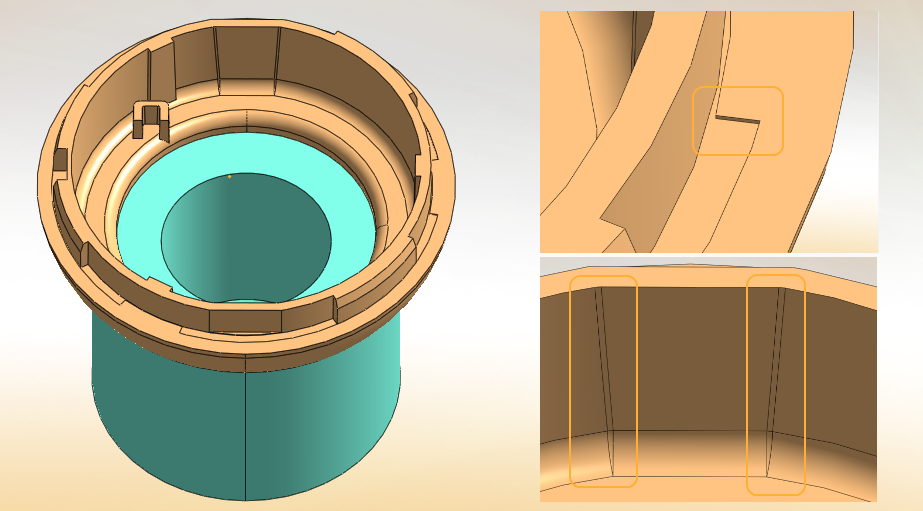

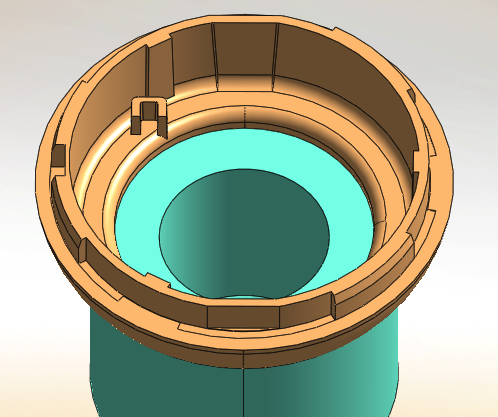

The quality of the mesh in the fluid domain is even more important than in the solid parts. Let’s take a look at the inner fluid domain (the air contained in the LED):

The mesh “seems” good, but we should be aware that the mesh quality is not something that can be checked so easily. Mesh quality check has to be done to confirm if we can use this mesh or if we need to remesh it.

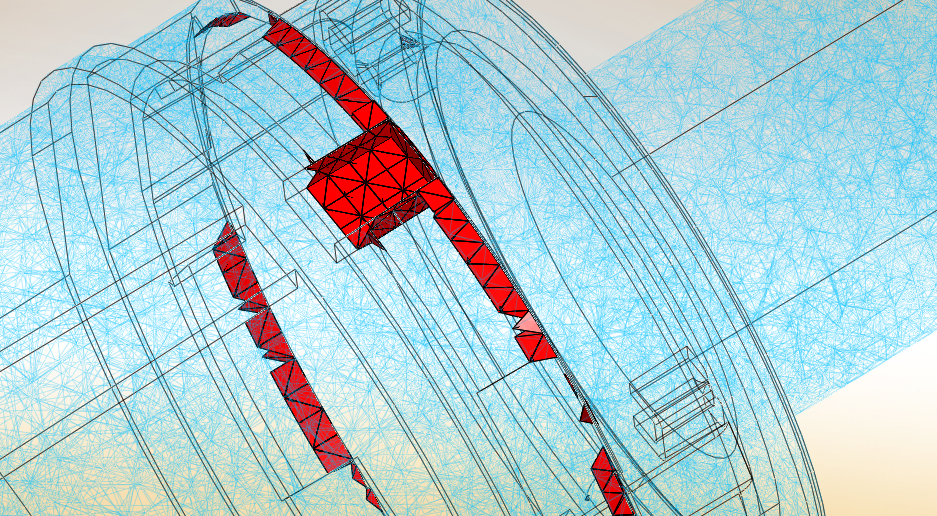

Let’s see closer:

These small faces will lead to divergence of the temperature around them at CFD contact between solid and fluid parts.

We have only one way to remedy to that, the model need to be simplified…

The best way to do is not to simplify the inner fluid part, but to simplify the solid part which causes the small faces in the inner fluid part. after simplification, the fluid part can be generated again using simple boolean operations.

I will show here a few methods that can be used to simplify the part.

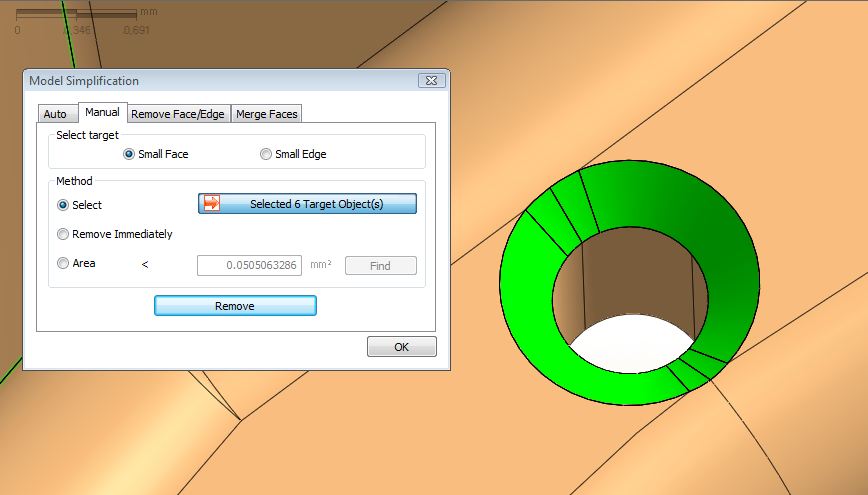

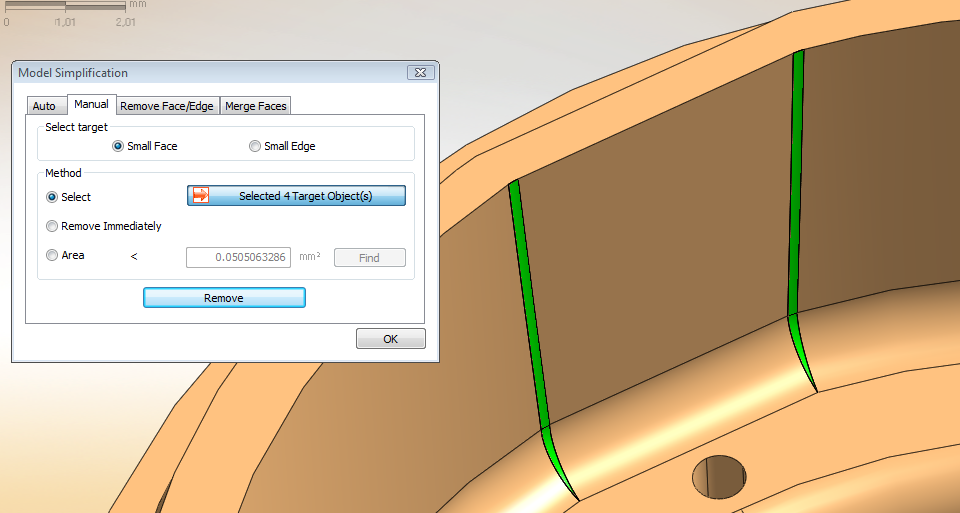

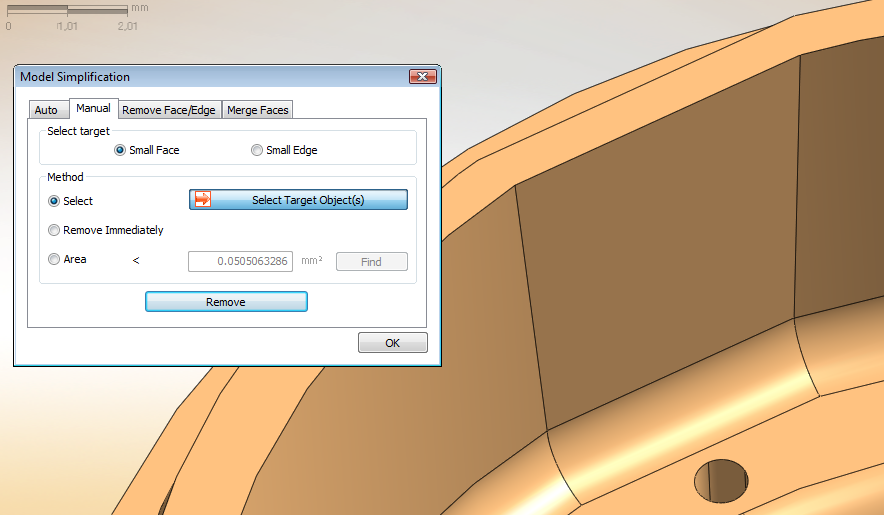

1. Use the simplification tools provided in your CAE software:

2. When model cannot be simplified using simplification tools, the best way is to come back to your CAD software to do the simplification job.

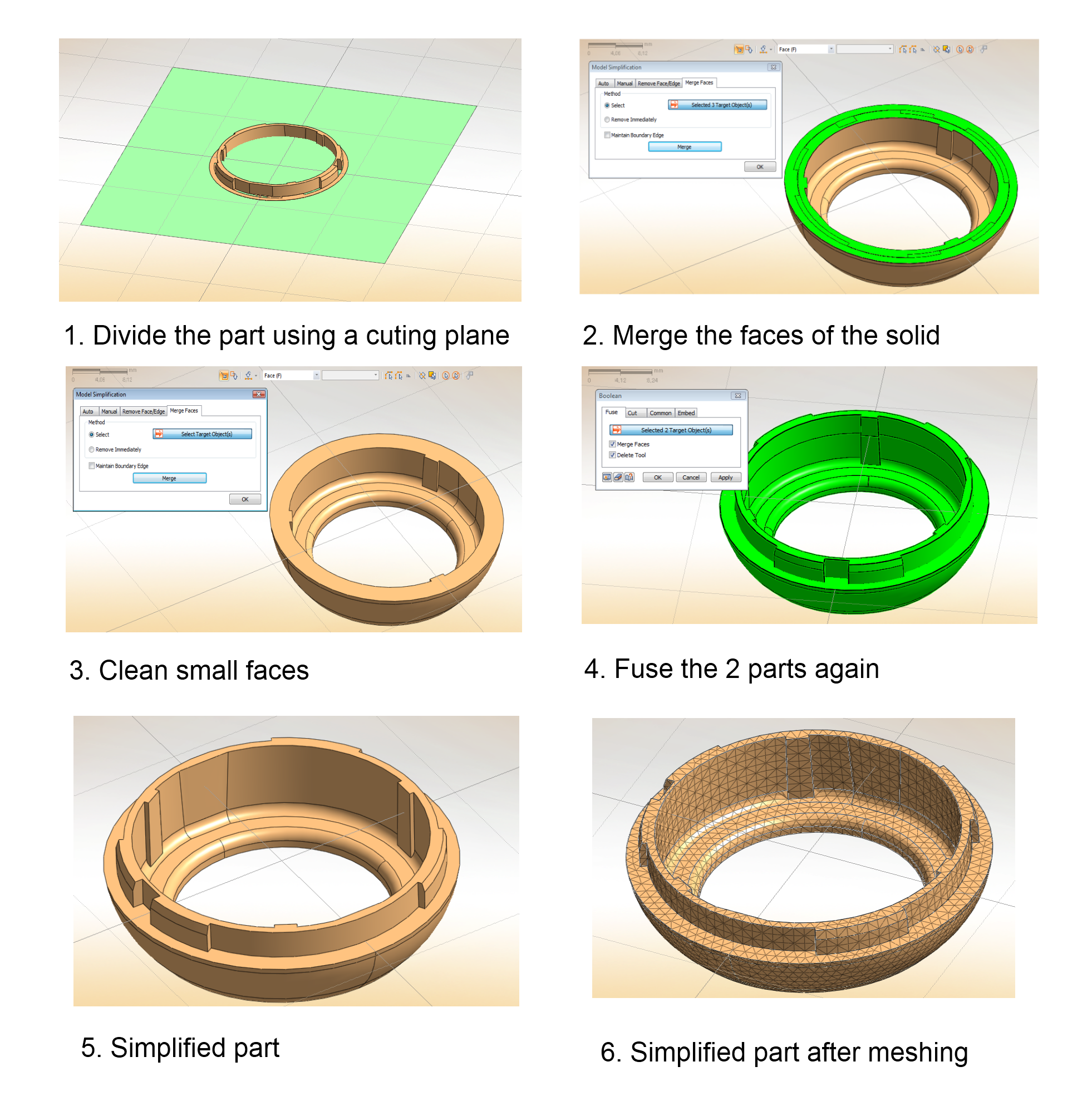

If you don’t have CAD software, you still have a way to simplify your model using simple boolean operations:

Actually, this is a method I invented myself, I don’t know how other CAE perform this kind of simplification… I guess using CAD is still the best way… If you have such experience of model simplification, let me a comment in the section below ! Thanks in advance to share your own experience ;-)

See you next week for another FEA interesting subject !

A bonus in video: how to simplify the sink part using boolean operations and simplification tools:

As several people asked for it, I am also providing the PDF of that article, for reference.

You can download it here

–Cyprien Rusu – FEAforall

Its great to read your blog.Thanks for the efforts you are giving to make things simple.I was wondering do you know any book which can be of great help? I want a book which will talk about what mesh to use shere to use and so on in terms of CAD analysis.

Thanks!

Great Job, Can you suggest me, “Materials for understanding Quality of Mesh”

How to Confirm my quality of mesh is good one? pls help

Thank you for you comment Parthiban, if you send me your Email, i will send you some document on mesh quality.

To confirm the quality of your mesh, you have usually some tools in the software you use to test the aspect ratio of the mesh for example. It will give you a first idea of the quality of your mesh (an aspect ratio >> 1 means that your mesh is very deformed).

you have also other ways to test the quality of the mesh other than aspect ratio.

Thanks for supporting the blog !

Great Job,as Pradipta Biswas asked, Can you suggest me, “Materials for understanding Quality of Mesh” and How to Confirm my quality of mesh is good one?.

My e-mail is job.guevarab@pucp.pe, and thank you for all the information you share.

Thanks alot, Cyprien for your blog!. You can send me the file : marwanzeitoun1@hotmail.co.uk

Hi Cyprien, I’d like a copy of the document for reference. Thank you very much!

Email: herbertlow_mha@kobaytech.com

Hi Cyprien, I’d also like a copy of the document, could you please share it? my email is: coroche@outlook.com

Great post!

Hi Cyprien,

I graduated sshipbuilding engineering department. I want to improve my career on fae/cae. May you advice me about improving path on fae from the begining. For example, should I repeat my mechanics of materials knowledge or etc.

Thank you for your help already now.

Hello Talha,

Sorry to answer a bit late to your post on Linkedin (yes I saw it…)

Thank you for reading my blog, I am happy that you can learn something in it !

To learn FEA Analysis, i would suggest that you begin by learning a specific software and testing some simple examples of mechanic of materials at the same time by comparing the results (the plate with a hole for example is a classic, you will find the video on my Youtube channel).

Do you have any software available in your university ? If not, let me know and i will see the possibility to provide you a student limited license of midas NFX.

You will learn more and more by trying the software I am sure.

If you look first at the book on FEA theory, there are some chances that you will be bored… so in my opinion, going from simple thing to complex thing is the right way to go !

Let me know if you have specific topics of interest and I will think about a post on the subject !

Cyprien

Hi Cyprien,

Thank you very much for all your concern.

I have been using ansys Workbench (Mechanical) for one month . I can understand its usage by following some video course. But, I can not interpret results . What I trying to learn is that what is the importance of theoretical Mechanics of mateials to understand and interpret our analysis . If it is a vital 1o learn fae, I will repeat mechanics of materials course. I don’t have enough time. That’s why ‘ I should decide What I will start from in a very short time. If you help me about it, I will be grateful.

Thank you very much again for all your concern .

Talha Ensar

Hello Talha,

yes, Mechanics of material is useful and you should know the basis out of it.

In my opinion some course about “Continuum Mechanics” would be even more useful.

Although the time is the same for everyone, you need to be efficient in the usage of your time. It will help you to learn more!

Cyprien

Hi Cyprien,

Thank you for all concern again and again.

Great information, I would like to know more about CAD models which contain small edges, doubled edges or very small faces which make very difficult to do the meshing or even if the CAD model is mesh, there is a problem with singular matrix (I read that post too), if you have more tutorial or document wich make me understand more about how to avoid this kind of problems if I also the person who do the CAD model or the person who try to solve the geometry problems before the meshing. I write my e-mail if you can share some documents.(job.guevarab@pucp.pe)

Thanks for your work, it is quite helpful and thank you very much for all your concern.

Job Guevara

hi, thanks for your effort to explain all of this, i am a beginner so i try to resolve a simple work with the heat sink about led light, can i send you my easy 3d model…. i use nx…thanks again

Hi, my self, Bharat Valand. I am FEA Engineer & doing FEA simulation. Thanks for your concern & appreciating your great effort. Its great information & helpful that you have provided.

Thanks for yout kind support. It will be great if you share some documents or books related to it.

My mail ID: bharatvaland003@gmail.com

Good blog cyprien. Can you please Explain more clearly about Aspect ratio?

Can you suggest me, “Materials for understanding Quality of Mesh” and How to Confirm my quality of mesh is good one?.

My e-mail is abdulsameer1110@gmail.com, and thank you for all the information you share.

Dear Sir,

In meshing tool for quality check, aspect ratio, skew angle, warpage angle, taper, Jacobian ratio, element length, twist angle are used. I want to know the significance of each of them. If possible then make an article on it.

It will help me as well as other FEA beginner.

Thanks and Regards,

Pranav Shukla

Hi Cyprien,

I also utilized the same procedure that you mentioned in article to build the FEA model from deburring/defeaturing CAD model in 2013. It’s really a convenient way to obtain the 3D model.

But I found in some circumstances, the pros of establishing the FEA model at CAE software is easier to do some slightly physical changes at current model, BTW, it’s really take time to get this benefits.

Thanks for your sharing!

Frank Tsai