product design

FEA can be used mainly in 3 ways in product design:

– As a tool for designers to help to create the right design

-As a tool to check the design

-As a tool to check the reasons why a product fails

Designing a product is a challenge

Designing a product is not an easy task and simulation can help in many ways during the design process after after, once the product is released and sold to clients.

Designing a product always involve the selection of an optimum design from a range of large possible choices. This is a difficult choice, because there are many variables to consider and the final design will have a big impact on the success of the product on the market.

What it is important to understand though, is that an optimum design doesn’t actually cost more time and money to design and produce. It might even cost less and everyone will be happier.

Why is it difficult to design a great product?

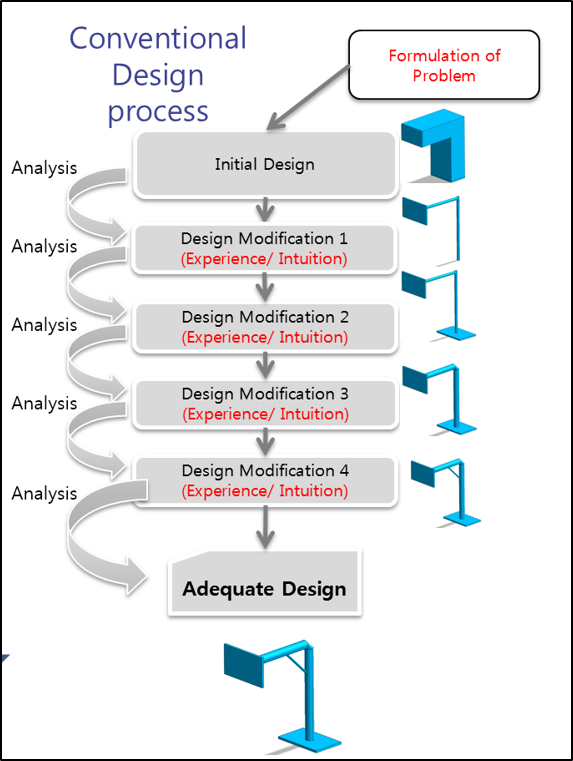

obviously, there are many reasons for that… Design is generally based on experience and so designers who “saw” more, are able to create better design. That’s the design by experience.

The problem is that this is entirely based on the skills on the designer and this is not a systematic way to do design a product.

Because of the difficulty for many designers to be creative enough, they generally tend to choose a design solution which is close to something that already exists.

How to search for better designs in a systematic, practical and affordable way?

FEA Simulation provides some tools to help the conception of products (Topology Optimization) & tools to check the design (linear static analysis).

Topology optimization can be used to help the designers to make the right choices and provide more ideas for design.

If you are interested by topology optimization, you can read this article: http://feaforall.com/2014/10/04/reduce-cad-design-cost-using-simulation/

Why is simulation used to check the product design?

Designing a product requires an enormous amount of experience and trial –errors.

Because of that the design should be checked at every step.

We want to be sure the product will be resistant enough to sustain the conditions of utilization and won’t fail under special circumstances

Simulation is the most used to verify why a product failed

Whatever you believe, product can always fail whatever the checking you did, because we can never predict everything.

When it fails, the engineer has to understand why it failed in order to improve the design.

I suggest you to watch this very interesting video about design failure:

You can also read this other article if this topic interests you:

Hi from West Australia! Thanks for the info and taking the

time to share it.

Hi, Awesome blog you got here, Thanks for the share and explaining the concept really well! A really helpful blog you got here.