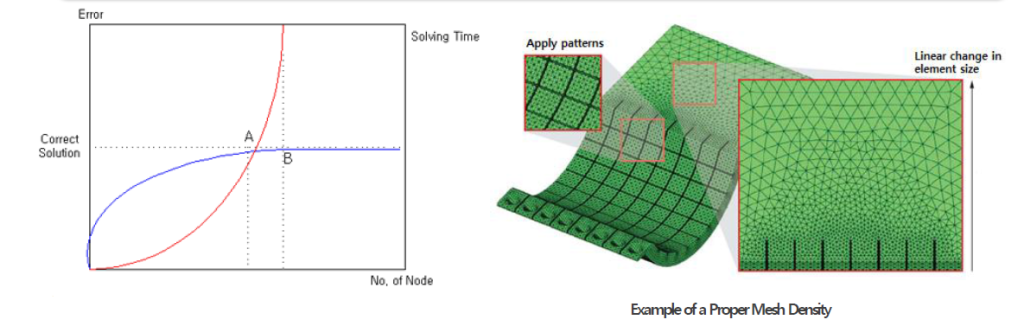

Every engineer doing FEA Analysis probably knows that increasing the number of elements is supposed to improve the accuracy of the solution.

This is true.

But, this also create some problems, because if you are perfectionist (I know a lot of engineers are), you may be thinking something like:

“If accuracy increases with the number of elements, let’s make the elements as small as possible and I will get the best accuracy ever”

BEWARE of this because this is dangerous…why?

1- Computational power required to compute your model increases exponentially with the mesh density

Even if you have the best computer in the world, there is a physical limit and even with 128 GB of RAM, you will not be able to calculate a model with elements which are too small because of the EXPONENTIAL growth of the computation time required.

To give you an example…

with an exponential law of Exp(x/100000-1), 200,000 elements will take 2.7 sec to compute, whereas 1,000,000 elements will take 8,103 sec (135 min) to compute.

(I just took an arbitrary exponential law for the sake of the demo)

Now I guess you can imagine why it is important to optimize the mesh density. You should have enough, but not much also, pretty vague huh… This will come with experience believe me. But keep reading and I’ll tell you more.

2- Small Mesh Density from the start slows down your analysis process

Imagine that you have a model to analyze. You know more or less what kind of result you want to get, but you don’t know exactly where maximum stress will appear.

So…what do you do??

Put the max number of elements and just calculate? Wrong answer

The “secret” that every analyst knows is that your analysis process has to be incremental.

– start with a relatively coarse meshed model –> get quick results

– Observe the zones where you have stresses appearing

– Refine the mesh in those areas and launch again the calculation

This is an iterative process that you have to do over and over again to get your final model ready.

This is how you get accurate results everywhere actually, not only in FEA… never expect to get all the results in one blow, you must have an incremental approach. Go from simple to complex.

There is no “Fits for all” solution, you have to investigate your model, put the efforts to build it correctly and you will get what you want.

The additional advantage to work incrementally is that your FEA modelling skills will sharpen at the same time and you will start to see how to build more and more complex models with less and less thinking.

Hi!

Do you think for a Modal analysis, the mesh, has the same impact than for stress analysis?

Best Regards

Jose

No, but it shoud be sufficient to bend or twist according to mode.

For Modal, the key is to use the amount of elements that can correctly represents your Mode Shape.

Something else: ALWAYS use Residual Vectors to improve the accuracy of your analysis.

In most cases, the Modal Analysis is just the beginning. Probably you’ll have to use it later for a Modal Transient Analysis or a Mod Harmonic Analysis. So, try to understand well the posterior analysis. This way, you’ll be able to perform better.

Last hint: use Strain Energy, Kinect Energy and Percentual Effective Mass when your aim is to make Design Changes, using Modal Analysis. Not always Mode Shapes can give you an obvious answer.

Regards,

Leo

I find that a good strategy to find an initial value for the mesh density is to take the value that is automatically computed by the meshing routine, and hence reduce it in regular decrements until mesh convergence is achieved.